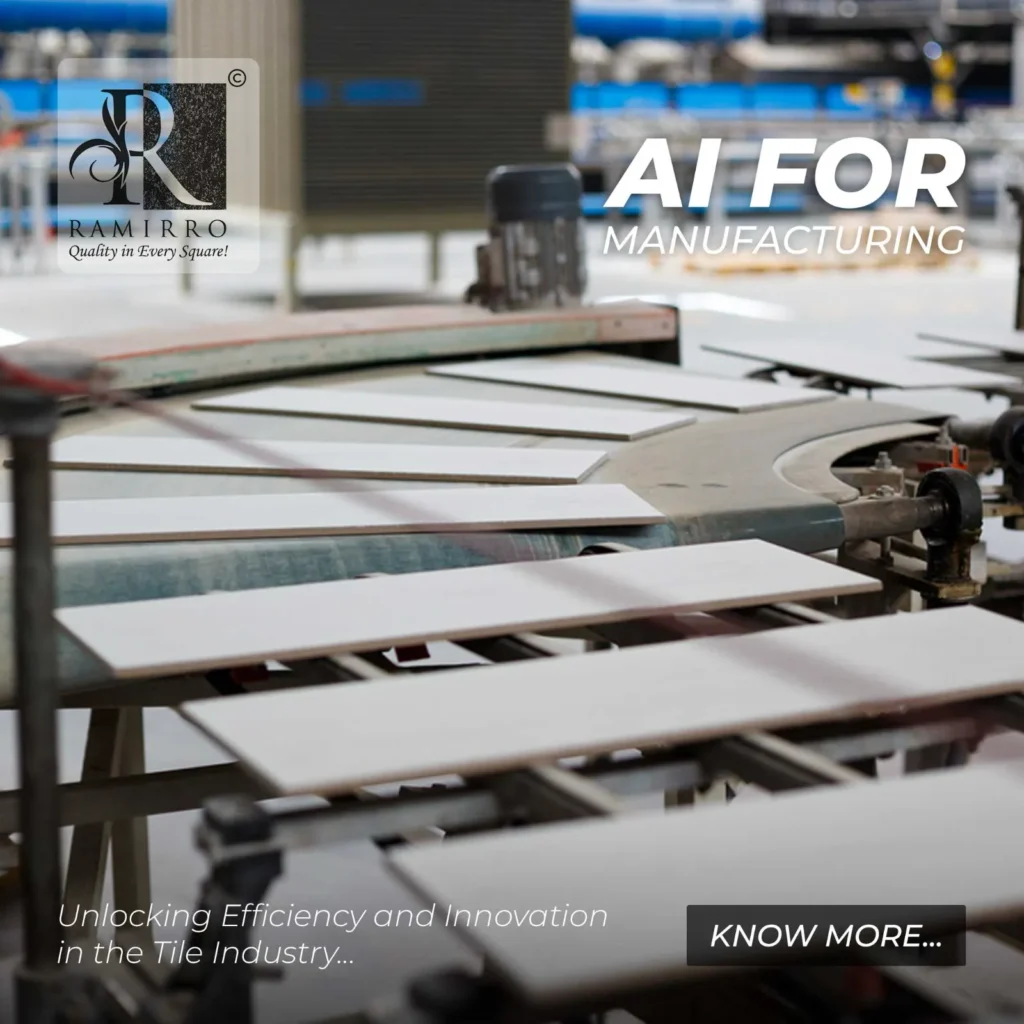

Uses of AI for Tiles Manufacturing

In today’s rapidly evolving manufacturing landscape, Artificial Intelligence (AI) is no longer a futuristic concept — it’s a powerful tool transforming how tiles are designed, produced, and delivered. AI in tile manufacturing goes far beyond automation; it unlocks new levels of efficiency, creativity, and precision across the entire production process. From intelligent design generation and real-time defect detection to smart packing and predictive supply chain planning, AI is reshaping every stage of the tile industry. This article explores how AI is driving this transformation — and why it’s the key to building a smarter, faster, and more sustainable future in tile production.

- Uses of AI for Tiles Manufacturing

- Overcoming Traditional Challenges in Tile Manufacturing

- Cutting-Edge AI (Artificial Intelligence) Tools Empowering Manufacturing

- AI for Interior and Architectural Design: Create Mockups for Living Rooms, Bedrooms, and Beyond

- AI Tools Optimizing Packing, Logistics, and Inventory Management

- AI in Enhancing Sales and Customer Relationships

- AI Tools for Predicting Market Trends and Consumer Preferences

- Powerful Use Cases of AI in the Manufacturing Industry

- Advanced AI in Manufacturing Process Optimization

- AI-Driven Innovation in Tile Product Lifecycle

- Overcoming Barriers to AI Adoption in Tile Manufacturing

- The Future of AI in Tile Manufacturing

- Discover Premium Tiles Crafted with Innovation — Only at Ramirro Ceramica

Overcoming Traditional Challenges in Tile Manufacturing

Traditional tile manufacturing has long faced challenges related to quality control, material waste, and operational inefficiencies. Manual inspections often miss subtle defects, leading to inconsistent product quality and increased waste. AI-powered visual inspection systems now offer a precise, real-time solution by detecting even the smallest surface flaws, ensuring greater consistency across every batch. Outdated processes frequently result in energy overuse, excessive raw material consumption, and unexpected machine downtimes. AI tools optimize energy usage, streamline production workflows, and predict maintenance needs before breakdowns occur—reducing costs and increasing output efficiency. As the industry faces growing demands for innovation, customization, and sustainability, AI is becoming essential for staying competitive. With its ability to analyze real-time data, automate decisions, and anticipate market trends, AI empowers manufacturers to future-proof their operations and lead the next era of smart tile production.

Cutting-Edge AI (Artificial Intelligence) Tools Empowering Manufacturing

AI in Product Design: Crafting the Perfect Tile

Artificial Intelligence is transforming how tile designs are imagined and executed. Using tools like generative design software, manufacturers can now explore thousands of design variations within minutes. These AI systems take into account factors like surface textures, pattern complexity, color compatibility, and even market-specific design preferences. They can also simulate how a tile will look under different lighting conditions or in various room settings — all before a single tile is produced. What once took weeks of manual trial-and-error can now be achieved in hours, allowing manufacturers to launch more innovative and market-ready designs faster than ever before.

Material Optimization with AI: Reducing Waste and Costs

Raw materials are one of the highest cost factors in tile production — and over use or miscalculations can lead to major waste. AI tools help solve this problem by analyzing production data to optimize material formulations and usage. Machine learning models can predict exactly how much raw material is needed for a specific tile type, surface finish, or batch size. This minimizes overproduction, reduces excess inventory, and ensures consistent product quality. Some AI systems also suggest alternative raw material combinations that maintain performance while lowering cost or environmental impact, making the production process both economically and ecologically smarter.

AI-Powered Color Selection for Interior Design

Choosing the right tile colors isn’t just about aesthetics — it’s also about matching consumer expectations and design trends. AI-powered color prediction tools can analyze millions of data points from sources like interior design websites, social media trends, online purchases, and design professional input. This allows manufacturers to identify rising color palettes that will likely dominate future interior design schemes. AI can recommend tile colors based on the psychological impact of color in different spaces — for example, suggesting cool tones for relaxation areas or vibrant hues for commercial settings. This level of insight helps create tile collections that are not only stylish but also emotionally and functionally aligned with modern living.

AI for Interior and Architectural Design: Create Mockups for Living Rooms, Bedrooms, and Beyond

Instantly Visualize Tiles in Realistic Room Layouts

AI-powered tools now make it possible to create highly realistic 2D and 3D room mockups using actual tile dimensions, textures, and lighting scenarios. Whether it’s a bedroom, living room, or commercial lobby, these visualizations show exactly how tiles will appear in a finished space — helping reduce uncertainty and increasing buyer confidence before installation begins.

Smarter Personalization for Architects, Designers, and Clients

AI platforms streamline the design process by offering real-time personalization based on user inputs like room type, style, lighting, and material preferences. These tools allow architects and interior designers to collaborate more effectively with clients, providing instant mockups that reduce back-and-forth and accelerate decision-making — all while maintaining design intent.

Enhancing E-Commerce and Design Decisions with AI Insights

Intelligent design platforms are also transforming online tile shopping. Interactive previews let users “try on” tiles in virtual spaces, while AI-backed systems suggest on-trend color palettes and layout combinations tailored to specific room functions. By combining aesthetics with data, AI is helping consumers and professionals make faster, smarter design choices.

AI Tools Optimizing Packing, Logistics, and Inventory Management

AI for Efficient Packing Systems: Streamlining Tile Packaging

AI systems can now automatically calculate the optimal packaging solutions based on tile dimensions, fragility, and shipping requirements. By determining the best fit and configuration for each shipment, these systems reduce material waste and minimize transportation costs, ensuring that each tile is packaged securely and efficiently.

Intelligent Inventory and Raw Material Management

With AI-powered analytics, manufacturers can optimize raw material inventories by accurately predicting future demand and adjusting stock levels in real time. This proactive approach helps to prevent both overstocking and under stocking, ensuring that production runs smoothly and waste is minimized.

Automated Logistics: AI in Tile Shipping and Distribution

Advanced AI tools also enhance logistics by determining the most efficient transportation routes, managing fleet schedules, and reducing shipping delays. By streamlining these processes, manufacturers can deliver products faster while significantly cutting transportation costs.

AI in Enhancing Sales and Customer Relationships

AI-Driven Sales Forecasting

Modern AI systems can analyze vast amounts of sales data, seasonal trends, and customer behavior to accurately forecast demand. This empowers manufacturers to optimize production schedules, manage inventory more effectively, and stay ahead of market trends — leading to better sales planning and reduced overproduction.

AI in Customizing Tile Solutions for Customers

AI tools allow sales teams to deliver customized tile solutions based on a customer’s specific design preferences, room dimensions, color palettes, and functional requirements. By offering tailored recommendations, brands can boost engagement, increase conversion rates, and enhance overall customer satisfaction.

Virtual Showrooms and Augmented Reality (AR)

AI-powered virtual showrooms and AR (a technology that superimposes a computer-generated image on a user’s view of the real world, thus providing a composite view) experiences let customers visualize tiles in their own spaces before buying. From browsing room-specific collections to “placing” tiles in kitchens, bathrooms, or commercial areas, this technology bridges the online-offline gap and makes the tile buying journey more interactive, immersive, and convenient.

AI Tools for Predicting Market Trends and Consumer Preferences

AI in Market Trend Analysis: Predicting Consumer Demands

AI-driven tools can scan and analyze global design movements, regional preferences, and purchasing behaviors to forecast emerging tile trends. This empowers manufacturers to stay ahead of the curve by producing styles, colors, and textures that align with current and future consumer demand.

Sentiment Analysis and Customer Feedback

AI-powered sentiment analysis tools dig into online reviews, social media conversations, and customer surveys to extract valuable insights. These systems detect patterns in praise or complaints, helping manufacturers quickly adjust product lines, improve service quality, and fine-tune marketing strategies.

Data-Driven Customization: AI in Tailoring Tile Products

By leveraging historical buying behavior and user interactions, AI can predict which tile designs, materials, and finishes resonate most with specific customer segments. This allows brands to offer hyper-personalized product recommendations — from trending marble-look tiles to customized geometric patterns — increasing customer satisfaction and boosting sales.

Powerful Use Cases of AI in the Manufacturing Industry

AI Applications Transforming Manufacturing Operations

One of the most significant benefits of AI in manufacturing is its ability to optimize manufacturing operations. Manufacturers use AI algorithms to monitor production processes in real time, identify bottlenecks, and automatically adjust variables to maintain consistency. AI models assist in reducing energy consumption, improving throughput, and minimizing manual intervention. These AI applications in manufacturing not only improve operational efficiency but also deliver measurable gains in productivity and sustainability — crucial factors for any modern manufacturing business.

Generative AI in Tile Design and Product Customization

Generative AI is revolutionizing how manufacturers create and customize tile products. These AI-powered systems analyze design trends, customer data, and spatial preferences to generate unique patterns, textures, and finishes. By using AI in this way, manufacturers can offer on-demand personalization without increasing production time or cost. This is a prime example of how artificial intelligence in manufacturing is enhancing both creative output and commercial scalability.

AI-Powered Quality Control and Predictive Maintenance

In traditional tile production, quality assurance and equipment maintenance are often reactive and prone to error. Today, AI use cases in manufacturing include real-time defect detection using computer vision and predictive maintenance powered by machine learning. These systems analyze sensor data to forecast when a machine might fail, allowing teams to intervene before costly breakdowns occur. This aspect of manufacturing not only reduces downtime but also extends equipment lifespan — a vital advantage for manufacturing companies seeking operational resilience.

Smart Inventory and Supply Chain Management with AI

AI technologies are also used in manufacturing to create smarter supply chains. AI-powered forecasting tools predict demand spikes, optimize procurement schedules, and ensure the right inventory levels across warehouses. This allows manufacturing companies to avoid overstocking or shortages and to reduce material waste. In the tile industry, where raw material availability and delivery timelines are critical, using AI in manufacturing operations has become a competitive necessity.

The Power of AI in Enhancing Selling and Presentation

AI can also add value beyond the factory floor. In tile merchandising, AI-driven platforms help personalize customer experiences by offering tailored product suggestions based on room size, design style, or even regional preferences. Augmented reality (AR) tools — a subset of AI — allow customers to visualize tiles in their actual spaces before buying, transforming the way manufacturers present and sell their products. These AI solutions improve decision-making for both sellers and buyers, leading to higher satisfaction and conversion rates.

Advanced AI in Manufacturing Process Optimization

AI in Predictive Maintenance: Preventing Equipment Failure

AI-powered predictive maintenance systems monitor machinery health in real time, using sensor data and pattern recognition to anticipate potential breakdowns before they happen. This helps manufacturers reduce unplanned downtime, extend the lifespan of expensive equipment, and ensure smoother production cycles.

AI in Real-Time Process Monitoring

AI continuously tracks key production parameters—such as pressure, speed, and material flow—across the tile manufacturing line. It automatically adjusts variables to maintain consistency, reduce defects, and optimize output, all without manual intervention. This level of control leads to higher-quality tiles with fewer errors.

Optimizing the Kiln Firing Process with AI

One of the most critical and sensitive stages of tile production is firing. AI analyzes temperature curves, humidity levels, and kiln speed to make real-time adjustments. This results in precise control over tile hardness, color consistency, and overall finish—reducing waste from over firing or under firing and improving yield quality.

AI-Driven Innovation in Tile Product Lifecycle

AI in Research and Development: Creating Cutting-Edge Tiles

AI is revolutionizing the R&D phase of tile manufacturing by enabling faster experimentation and smarter innovation. Machine learning algorithms analyze vast datasets—including material behavior, design performance, and consumer preferences—to identify which tile formulas, finishes, and structures are likely to succeed. Instead of relying solely on trial-and-error methods, AI can simulate product outcomes in digital environments, saving time and resources. This leads to the creation of advanced tiles with enhanced durability, slip resistance, antibacterial properties, or aesthetic appeal, all tailored to market demands.

Sustainability Through AI in Tile Manufacturing

Energy-intensive processes—like raw material refinement, kiln firing, and post-processing—are major contributors to a tile factory’s environmental footprint. AI systems optimize each phase by analyzing energy usage patterns and adjusting parameters in real time to reduce unnecessary consumption. For example, AI can fine-tune kiln temperatures and drying cycles to conserve fuel without compromising tile quality. AI-powered systems can reduce scrap generation by detecting and correcting flaws early in the process, further minimizing material waste and lowering CO₂ emissions.

Circular Economy with AI: Recycling and Reusing Tiles

AI is also playing a pivotal role in supporting a circular economy in the tile industry. Advanced image recognition and material analysis tools can identify reusable tiles, sort broken or defective pieces by composition, and suggest how waste can be reintegrated into the production cycle. AI-driven robotics can even automate the separation and processing of recyclable materials from demolition waste. By intelligently managing tile reuse and waste recovery, manufacturers reduce their dependency on virgin raw materials and take meaningful steps toward closed-loop manufacturing systems.

Overcoming Barriers to AI Adoption in Tile Manufacturing

Investment and ROI: Weighing the Benefits

Adopting AI in tile manufacturing often requires significant upfront investment — including the cost of software platforms, smart sensors, high-performance computing infrastructure, and system integration. For many manufacturers, especially mid-sized operations, this raises concerns about return on investment (ROI). However, when implemented strategically, AI can deliver measurable gains in efficiency, defect reduction, material savings, and faster product development. Over time, these operational improvements often outweigh the initial costs, especially when AI enables predictive planning, reduced downtime, and data-driven decision-making.

Training and Skill Development for AI Integration

AI doesn’t just change machines — it transforms the way people work. One of the biggest challenges in AI adoption is the skills gap among existing staff. Operators, engineers, and managers must be trained to interpret AI-generated data, oversee intelligent systems, and collaborate with machine-learning algorithms. Upskilling programs, internal training, and partnerships with AI solution providers are crucial for smooth adoption. Investing in human capital ensures that employees can adapt to automation, rather than being displaced by it — making AI a tool for empowerment, not replacement.

AI Data Security: Protecting Proprietary Information

AI systems thrive on data — from production metrics and customer preferences to proprietary tile formulations and design files. But this reliance on data also introduces new risks. If not properly secured, sensitive business information could be exposed to cyber threats or unauthorized access. To overcome this, manufacturers must implement robust data governance frameworks that include encrypted communication, strict access controls, regular vulnerability audits, and compliance with global data protection regulations (such as GDPR or ISO/IEC 27001). Ensuring data security is not just a technical necessity — it’s a cornerstone of trust in the age of smart manufacturing.

The Future of AI in Tile Manufacturing

Collaborative AI and Human Workforces: The Future of Manufacturing

As AI becomes more deeply integrated into tile manufacturing, the focus is shifting from replacement to collaboration. Rather than eliminating jobs, AI will augment human capabilities — taking over repetitive, data-heavy tasks while empowering workers to focus on creative, strategic, and supervisory roles. For example, AI can handle real-time monitoring and predictive maintenance, while humans make decisions about design direction, production priorities, and customer relationships. This synergy leads to safer workplaces (by reducing manual labor risks), more efficient processes, and a more innovative culture where humans and machines solve complex problems together.

AI and the Global Tile Market: A Shift Towards Customization

The tile industry is moving away from one-size-fits-all production toward hyper-customization — and AI is making it possible. By analyzing regional style trends, customer behavior, and even architecture-specific needs, AI enables manufacturers to develop tile lines tailored to specific markets or even individual clients. Whether it’s a specific pattern inspired by local heritage or a color scheme matched to a customer’s interior palette, AI-driven design tools allow for mass personalization at scale. This gives manufacturers a competitive edge in global markets where flexibility, speed, and differentiation matter more than ever.

Discover Premium Tiles Crafted with Innovation — Only at Ramirro Ceramica

Step into a world where design meets technology — with premium tiles exclusively from Ramirro Ceramica. Known for blending timeless style with cutting-edge innovation, Ramirro Ceramica offers tiles that are not only visually stunning but also engineered for lasting performance. Whether you’re renovating a cozy home or designing a bold commercial space, our expertly crafted collections bring elegance, durability, and smart functionality to every surface. Explore how Ramirro Ceramica is redefining what premium tiles can be — one innovative creation at a time.

Shop Now | Chat With Expert | View Catalogue

Why Should You Trust us?

Here’s what you get out of our article. Our team have various Ceramic Experts with experience of more than 25 Years, researches on problems our customer faces in tiling industry.

Ramirro Ceramica, – One of The Leading Tiles Manufacturer and Supplier globally, helps you people gain knowledgeable insight before making your purchase decision for products related to the floor and wall tiles.

So, we have closely monitored all kinds of trends in the ceramic tiles manufacturing world, from the old days of clay and plain color to modern digital, realistic-looking designs printed on ceramics with high-depth effects.

Our tiling Experts have seen thousands of different tiles patterns, sizes, materials, pricing, and installation techniques throughout their career.

Their expertise shared with you in simplified and organised way, helps you choose and make better decision before purchasing any flooring option available in market.

Brief about Company:

Ramirro is one of the finest Tiles manufacturers in India manufacturing porcelain and ceramic tiles. Our products have a variety of sizes and types of tiles ranging from Ceramics, porcelain, Full body etc. This helps you choose the perfect fit for your project. Plus, our collection will help you get inspiration from the architect’s design.

Here’s some more helpful links that showcase our users trust on Ramirro Ceramica Brand:

– Growth in International Market

– Trusted and Licensed Exporter

– Manufacturing Plant in India

Here’s our social proof by LinkedIn competing with top known global tiling brands: