“Quality is first engineered; only then it is inspected”- JRD TATA

Quality Control is one of the major and heavily invested part in making of product, Preventative action from our side is key to make sure that what you are exporting is safe and fit for purpose. We ensure you that we comply with standards, reduce product failures and pass quality control standards set for our product .

We provide transparency in our methods and work to satisfy customers requirements. Continuously improve the effectiveness of both the quality management system and the provision of our all products and services .

Ramirro Ceramics manufactures ceramic tiles according to the latest version of ISO 9001;2015, Its Tiles Testing Laboratory is operating in accordance to QMS accredited by affiliation.

- Setting and reviewing measurable quality objectives and targets, which address the risks and opportunities within the company, and ensuring those objectives are met.

- Providing the necessary resources and ensuring responsibilities and authorities are determined and communicated throughout the company.

- Monitoring the conformity of products to standard and contractual requirements.

- Reviewing the effectiveness of the quality management system on a regular basis and assessing opportunities for its continual improvement. Seeking structured feedback from our customers.

- Ensuring everything we do is always carried out in accordance with stated methods and customers’ requirements.

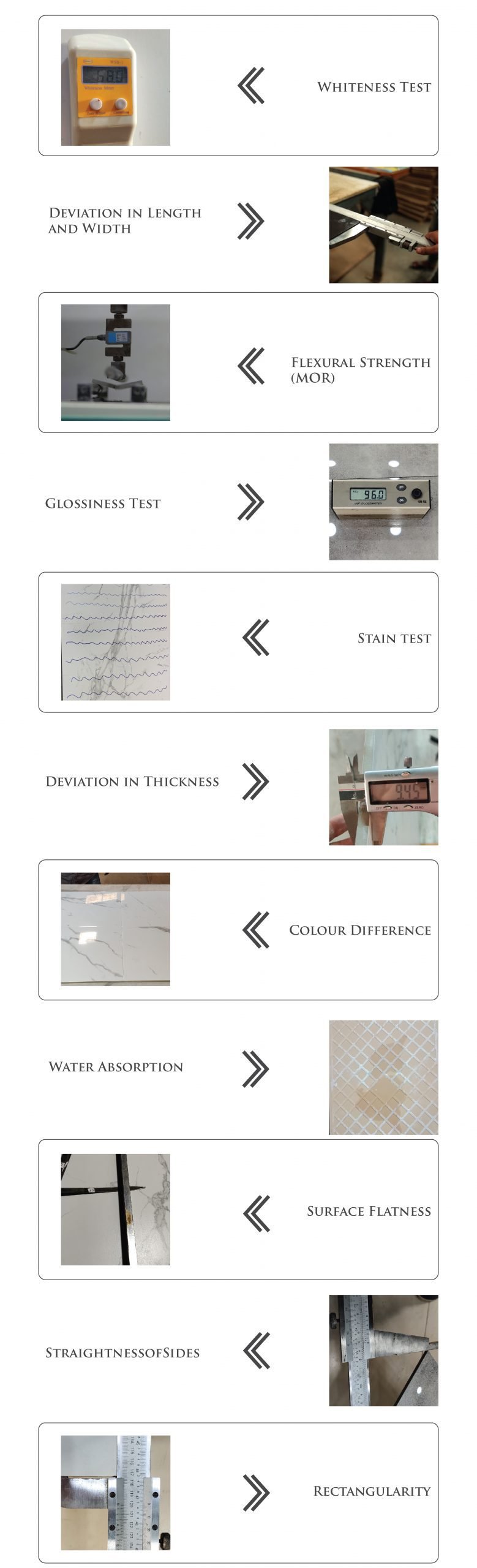

Whiteness Test

A whiteness test is needed in the ceramic tiles industry to ensure consistent color quality of the tiles. This is important because variations in color can affect the aesthetic appeal of the tiles and may be noticeable to customers. The test measures the degree of whiteness in the tiles and helps manufacturers maintain a high level of quality control.

Deviation in length and width test

The deviation in length and width test is needed in the ceramic tiles industry to ensure that the tiles meet the required size specifications. This is important because variations in size can affect the ease of installation and the overall look of the finished product. The test measures the degree of deviation from the standard size and helps manufacturers maintain a high level of quality control.

Flexural strength test

The flexural strength test is needed in the ceramic tiles industry to determine the strength and durability of the tiles. This test measures the maximum load that a tile can withstand before breaking, and it helps manufacturers ensure that the tiles can withstand the stresses of everyday use. The test is important because tiles with low flexural strength may crack or break easily, leading to costly repairs and customer dissatisfaction.

Glossiness test

The glossiness test is needed in the ceramic tiles industry to ensure consistent surface finish quality of the tiles. This is important because variations in glossiness can affect the aesthetic appeal of the tiles and may be noticeable to customers. The test measures the degree of reflectivity of the tile surface and helps manufacturers maintain a high level of quality control.

Stain test

The stain test is needed in the ceramic tiles industry to determine the resistance of the tiles to various types of stains such as oil, ink, and chemicals. This test helps manufacturers ensure that the tiles can withstand exposure to potentially staining substances without being permanently discolored or damaged. The test is important because tiles that stain easily may not be suitable for certain applications and can lead to customer dissatisfaction.

Deviation in thickness test

Color difference test

Water absorption test

Surface flatness test

Straightness of side test

The straightness of side test is needed in the ceramic tiles industry to ensure that the sides of the tiles are straight and even. This test helps manufacturers identify any irregularities, such as bowing or warping, that may affect the installation or appearance of the tiles. The test is important because tiles with uneven sides may not fit properly during installation, leading to potential safety hazards and aesthetic issues.

Rectangularity test

The rectangularity test is needed in the ceramic tiles industry to ensure that the tiles have 90-degree angles and meet the required rectangular shape. This test helps manufacturers identify any irregularities or deviations from the desired shape that may affect the installation or appearance of the tiles. The test is important because tiles with non-rectangular shapes may not fit properly during installation, leading to potential safety hazards and aesthetic issues.

Read More: How to Check Ceramic Tiles from a Customer & Importer Perspective?