- From Rockets to iPhones: Unveiling the Unbreakable World of Ceramics

- The Science Behind Ceramics

- Ceramics in Space Exploration: SpaceX

- Ceramics in Consumer Technology: Apple

- Ceramics in Aerospace: A Closer Look at Materials

- Ceramics in Consumer Electronics: More Than Just Glass

- Other Fascinating Applications of Ceramics

- Ceramic Technology and Sustainability: The Eco-Friendly Edge

- The Future of Ceramics

- The Power of Ceramics: High-Tech Applications Across Industries

- Purchase the Best Types of Ceramics and Porcelain Tiles at Ramirro Ceramica

- References/Further Reading

From Rockets to iPhones: Unveiling the Unbreakable World of Ceramics

Ceramics are no longer just for tiles and pottery—they are transforming the world of technology. From shielding SpaceX rockets against extreme heat to making iPhone screens tougher than ever, advanced ceramics play a crucial role in modern innovation. These high-performance materials offer unmatched durability, heat resistance, and strength, making them essential for aerospace, electronics, and beyond. At Ramirro Ceramica, we understand the power of ceramics in both design and technology. In this article, we’ll explore how ceramics are revolutionizing industries, proving they are more than just beautiful surfaces—they are the future of unbreakable innovation.

The Science Behind Ceramics

Definition of Ceramics

Ceramics are inorganic, non-metallic materials that are formed by the application of heat and subsequent cooling. Traditionally, ceramics include everyday items such as pottery, bricks, tiles, and porcelain. Advanced ceramics are specially engineered for high-performance applications and are found in fields like aerospace, medicine, and electronics. These advanced ceramics are formulated with precise compositions and microstructures to enhance specific properties, making them essential components in cutting-edge technology and modern innovations.

Key Properties of Ceramics

Ceramics are celebrated for their remarkable properties that make them highly desirable in a variety of applications. Their durability and strength ensure that they can withstand significant physical stress and wear, making them ideal for both industrial and consumer products. Ceramics exhibit exceptional heat resistance and thermal stability, enabling them to perform reliably even in extreme temperature conditions. Their chemical resistance allows them to endure harsh environments without degrading, while their lightweight nature contributes to improved efficiency in applications where weight is a critical factor.

How Ceramics Are Made

The production of ceramics involves a series of carefully controlled processes. It begins with the selection of raw materials, which can include natural clays for traditional ceramics or engineered powders like alumina, zirconia, or silicon carbide for advanced ceramics. These materials are mixed with additives and water to form a malleable paste, which is then shaped into the desired form through methods such as molding, extrusion, or casting. Once shaped, the material is fired in a kiln at high temperatures—a process that transforms the material’s structure through sintering. The firing process not only hardens the ceramic but also enhances its mechanical and thermal properties. Finally, additional finishing processes like glazing or polishing may be applied to achieve the required surface quality and performance characteristics.

Ceramics in Space Exploration: SpaceX

The Role of Ceramics in SpaceX Rockets

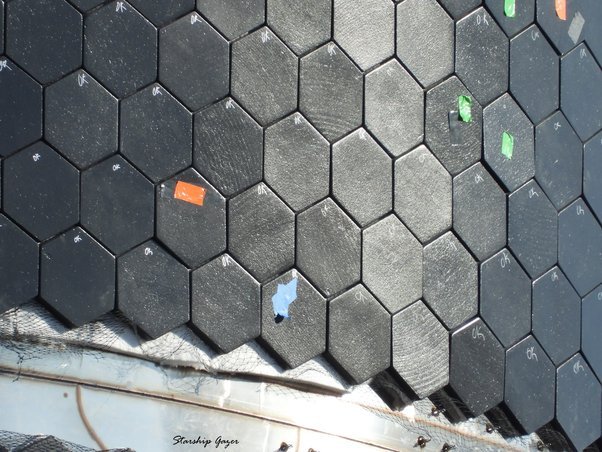

Ceramics play a critical role in the construction and protection of SpaceX rockets by serving as essential components in their thermal protection systems. During the intense phases of launch and especially re-entry, rockets are subjected to extreme heat generated by atmospheric friction. Ceramics are employed in the form of heat shields or protective tiles that can withstand these extraordinary temperatures. Their ability to endure high thermal loads and provide insulation helps to protect sensitive internal components from damage, ensuring the integrity and reusability of the spacecraft. The inherent heat resistance of ceramics is particularly important during re-entry, where managing the rapid temperature changes is crucial to avoid structural failures.

Specific Examples

SpaceX has integrated advanced ceramic materials into several of its key spacecraft, notably in the Falcon 9 and Starship designs. For example, the Falcon 9 utilizes ceramic coatings and specialized composite materials in certain areas of its structure to mitigate heat buildup and protect its re-entry components. These ceramic-based solutions contribute to improved thermal stability and enhance the overall durability of the rocket during repeated launches and landings. In the case of Starship, which is designed for deep-space missions and longer-duration flights, ceramics—often in the form of Ceramic Matrix Composites (CMCs)—are expected to provide even greater performance advantages. These materials not only offer superior heat resistance but also reduce the overall weight of the craft, leading to increased fuel efficiency and potentially longer mission durations. The performance advantages of these ceramic technologies include increased resilience against thermal shock, improved longevity of reusable parts, and enhanced safety margins during critical phases of flight.

Ceramics in Consumer Technology: Apple

The Role of Ceramics in Apple Products

Apple has long been at the forefront of integrating innovative materials into its product designs, and ceramics are no exception. The introduction of Ceramic Shield technology in iPhones marks a significant leap in durability and scratch resistance. This advanced material is engineered by infusing nano-ceramic crystals into the glass, creating a surface that is not only more resistant to impacts but also better able to withstand daily wear and tear. The use of ceramics in Apple devices means that the screens are less prone to scratches and cracks, offering users enhanced longevity and a consistently premium experience. This technological integration is a testament to Apple’s commitment to quality and innovation, ensuring that its products not only look great but also stand up to the rigors of everyday use.

Specific Examples

The latest iPhone models showcase the benefits of Ceramic Shield technology. Developed through a close collaboration with materials experts and leveraging cutting-edge nanotechnology, the Ceramic Shield was introduced to significantly improve the device’s durability. User experiences have reflected these advancements, with many noting the screen’s robust resistance to scratches and impacts in real-world scenarios. In tests comparing the Ceramic Shield to conventional glass, the enhanced toughness of the ceramic-infused screen has become apparent, providing greater confidence for users prone to accidental drops and everyday scuffs.

Ceramics in Aerospace: A Closer Look at Materials

In aerospace technology, ceramics are revolutionizing design and performance, particularly through the use of Ceramic Matrix Composites (CMCs). These advanced materials are engineered for critical applications in engines, rockets, and spacecraft, where their remarkable heat resistance and structural integrity allow them to endure extreme temperatures and thermal stresses. CMCs not only handle high temperatures effectively but also contribute significantly to spacecraft reusability by reducing thermal damage during repeated launches and re-entry maneuvers. Innovative ceramic-based tiles have enhanced safety and cost-efficiency in space exploration by providing superior insulation while lowering maintenance and overall vehicle weight. These advancements underscore the pivotal role of ceramics in pushing the boundaries of aerospace engineering, ultimately paving the way for more durable and efficient space missions.

Ceramics in Consumer Electronics: More Than Just Glass

In consumer electronics, ceramics are emerging as a game changer that goes far beyond traditional glass applications. Advanced ceramics are now being integrated into a variety of electronic devices—from wearables and automotive sensors to AI robots—thanks to their exceptional thermal stability, durability, and electrical insulation properties. These materials enhance performance by serving as critical components in chips, connectors, and enclosures, where they improve heat dissipation, reduce interference, and ensure long-term reliability under demanding conditions. The industry’s shift toward ceramics is not only about boosting performance; it’s also a move toward sustainability. By extending the lifespan of products and reducing the need for frequent replacements, ceramic materials contribute to creating more eco-friendly, long-lasting electronics that meet the modern consumer’s demand for durability and efficiency.

Other Fascinating Applications of Ceramics

Industrial Uses

Ceramics are increasingly making their mark in industrial applications beyond just aerospace. In sectors like automotive manufacturing, ceramics are utilized for producing lightweight components that do not compromise on strength or durability. Their resistance to heat and wear makes them ideal for high-performance parts, such as engine components and brake systems, which benefit from ceramics’ low thermal expansion and excellent thermal stability. This integration of ceramics into industrial design not only boosts efficiency and performance but also contributes to reducing the overall weight of vehicles and machinery, leading to enhanced fuel efficiency and lower emissions.

Medical Applications

In the medical field, ceramics have become invaluable due to their biocompatibility and long-lasting performance. They are commonly used in the development of prosthetics and implants, where the material’s inert nature prevents adverse reactions when in contact with human tissue. Ceramic components are favored for hip and knee replacements, dental implants, and bone substitutes because they offer high mechanical strength while mimicking the properties of natural bone. The longevity and resistance to wear of ceramics help ensure that these medical devices remain functional and safe over extended periods, significantly improving patient outcomes and quality of life.

Building Materials

The use of ceramics in the construction industry has long been established, and today’s innovations have only expanded their role. Traditional ceramic products such as tiles and bricks remain essential for their durability and aesthetic appeal, but modern ceramic materials are now also employed for advanced insulation and sustainable building practices. Their ability to regulate temperature and resist environmental degradation makes ceramics an excellent choice for energy-efficient construction. In sustainable building projects, ceramics contribute to reduced energy consumption and lower maintenance costs while providing a durable, long-lasting solution that meets the demands of modern architecture and urban development.

-

DOVE – Grey Full Body Tiles

DOVE – Grey Full Body Tiles -

SINTETICO-GREY Marble Look Porcelain Tiles

SINTETICO-GREY Marble Look Porcelain Tiles -

SINTETICO BIANCO Marble Look Porcelain Tiles

SINTETICO BIANCO Marble Look Porcelain Tiles -

SAHARA-GREY Marble Look Porcelain Tiles

SAHARA-GREY Marble Look Porcelain Tiles -

MYSTIQUE CREMA Marble Look Porcelain Tiles

MYSTIQUE CREMA Marble Look Porcelain Tiles -

MONTERA RIO Marble Look Porcelain Tiles

MONTERA RIO Marble Look Porcelain Tiles -

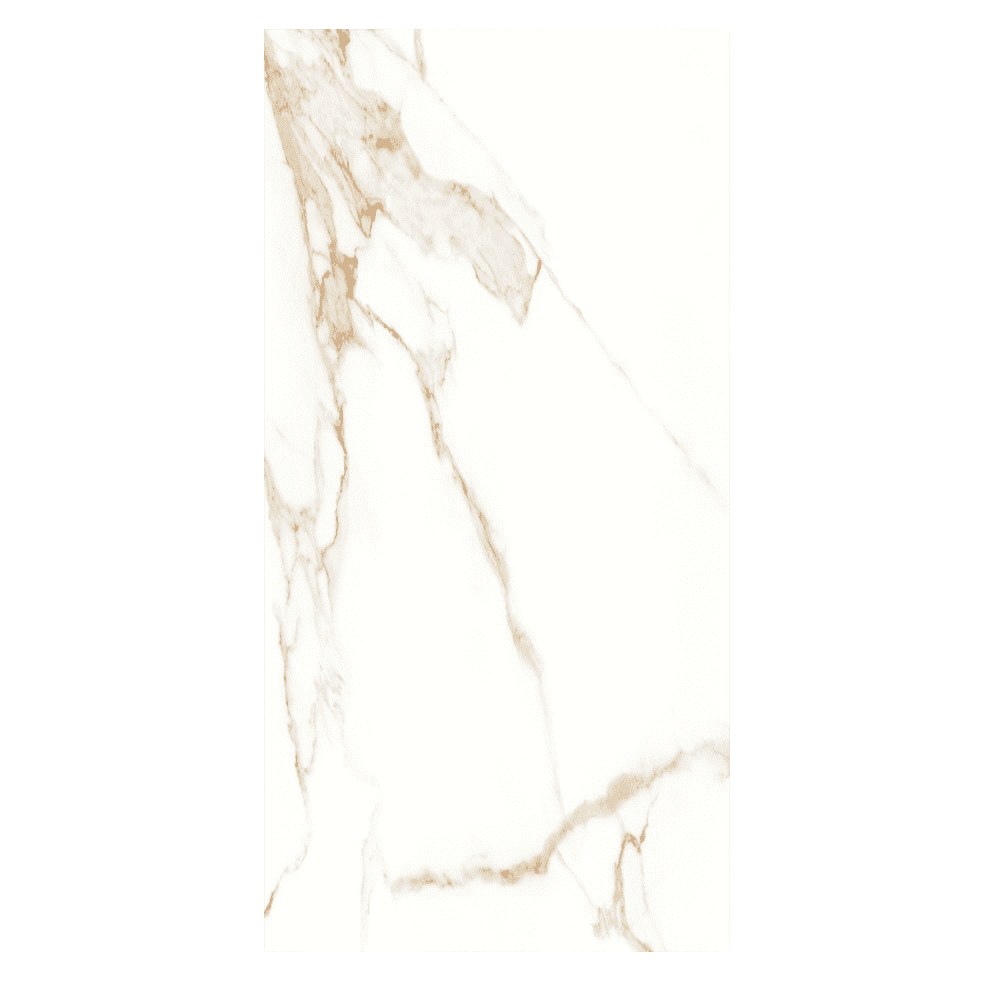

CALCATTA ORO Marble Look Porcelain Tiles

CALCATTA ORO Marble Look Porcelain Tiles -

APEN SILVER Marble Look Porcelain Tiles

APEN SILVER Marble Look Porcelain Tiles -

TERRAZZO BEIGE Marble Tile Design for Porcelain

TERRAZZO BEIGE Marble Tile Design for Porcelain -

TROPICANA WHITE Marble Tile Design for Porcelain

TROPICANA WHITE Marble Tile Design for Porcelain -

WILLIAM GREY Marble Tile Design for Porcelain

WILLIAM GREY Marble Tile Design for Porcelain -

TROPICANA CREMA Marble Tile Design for Porcelain

TROPICANA CREMA Marble Tile Design for Porcelain -

TRAVENTINO ROYAL Marble Tile Design for Porcelain

TRAVENTINO ROYAL Marble Tile Design for Porcelain -

STATUARIO PEARL Marble Tile Design for Porcelain

STATUARIO PEARL Marble Tile Design for Porcelain -

STATUARIO GOLD Marble Tile Design for Porcelain

STATUARIO GOLD Marble Tile Design for Porcelain -

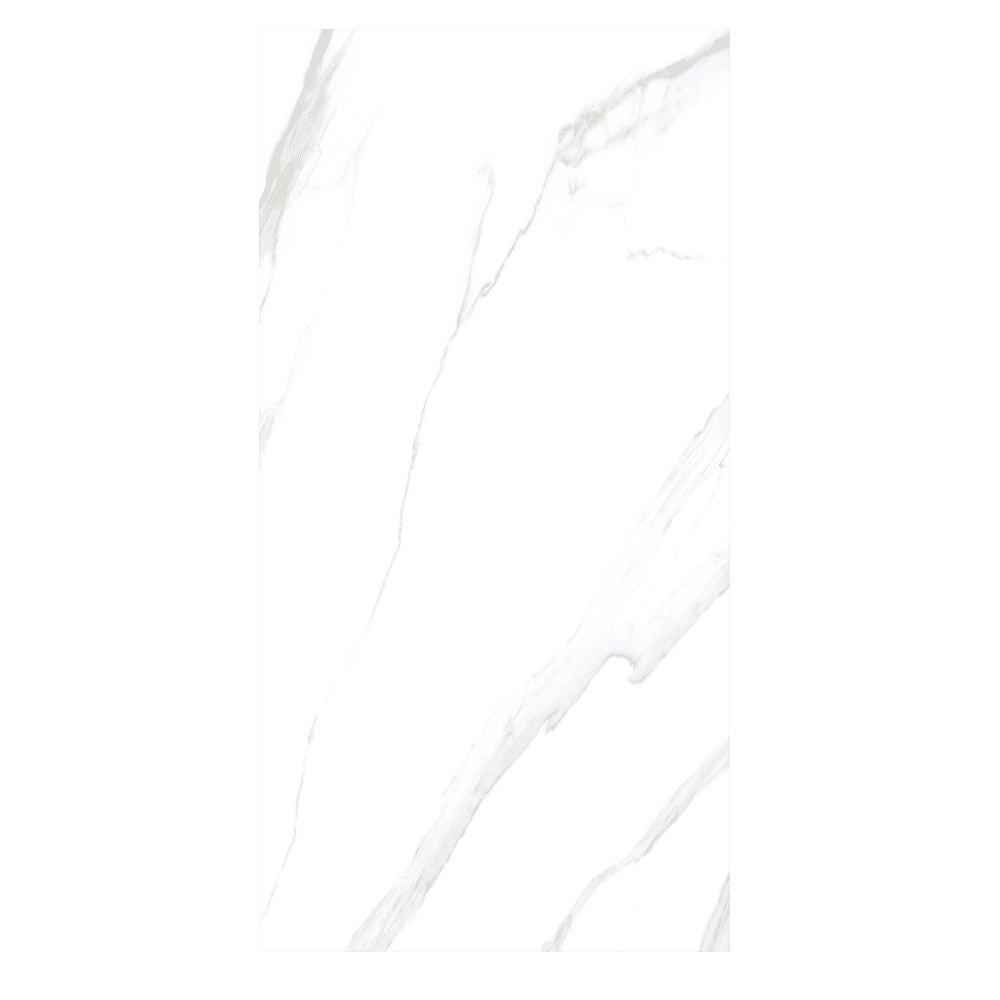

SEAMLESS STATUARIO Marble Tile Design for Porcelain

SEAMLESS STATUARIO Marble Tile Design for Porcelain -

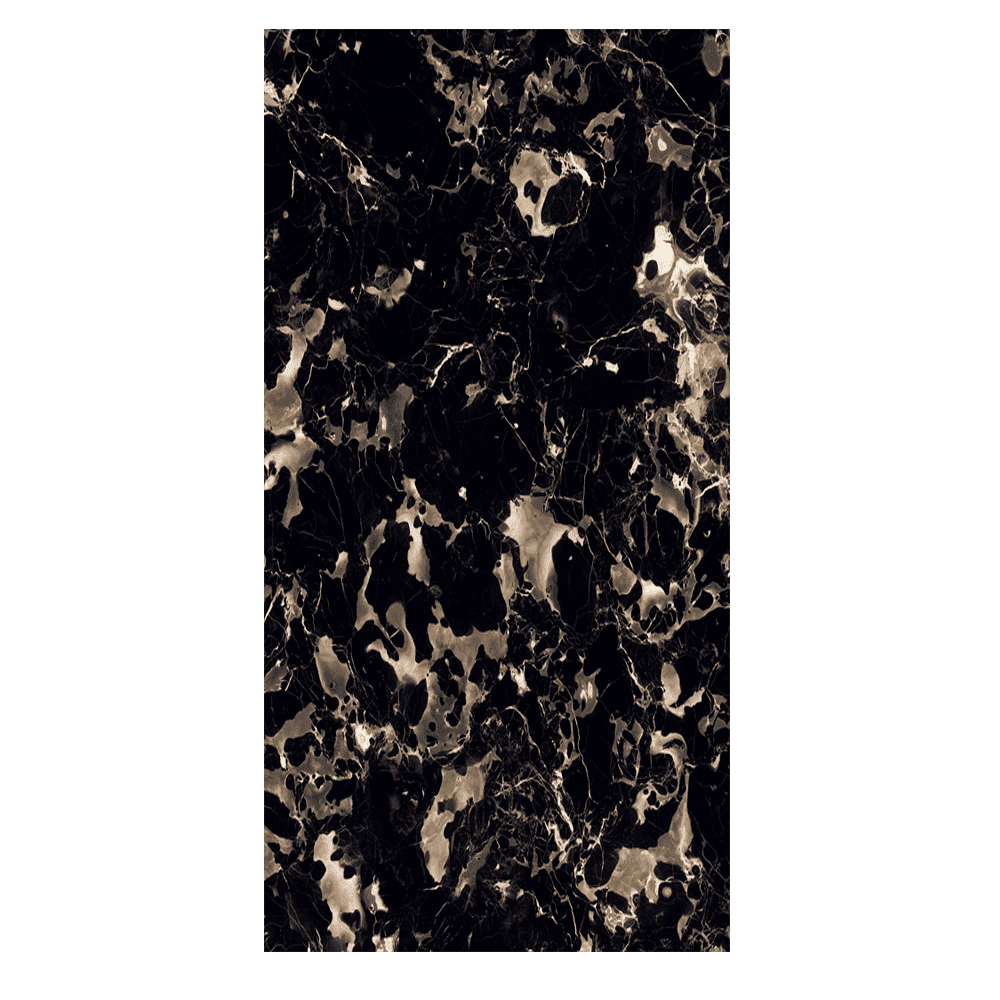

PORTORO BLACK Marble Tile Design for Porcelain

PORTORO BLACK Marble Tile Design for Porcelain -

NOVANA GREY Marble Tile Design for Porcelain

NOVANA GREY Marble Tile Design for Porcelain

Ceramic Technology and Sustainability: The Eco-Friendly Edge

Ceramics stand out as a sustainable and eco-friendly material choice due to their recyclability and energy-efficient production processes. Their inherent durability extends the lifespan of tech products and critical aerospace components, which in turn helps reduce electronic waste and the overall carbon footprint. In space missions, the use of high-performance ceramics minimizes the need for frequent part replacements and extensive repairs, contributing to lower resource consumption and emissions. In consumer electronics, ceramic components such as those found in smartphones and other devices ensure long-lasting performance, reducing the frequency of replacements and the resultant e-waste. Together, these factors position ceramics as a key material in driving forward sustainable practices across diverse industries, proving that advanced ceramic technology not only meets high-performance demands but also supports environmental conservation.

The Future of Ceramics

Trends in Ceramic Technology

The future of ceramics is being defined by rapid advancements in nanotechnology and the emergence of smart ceramics. These innovations are enabling the design of materials with finely tuned properties at the molecular level, leading to ceramics that are not only stronger and lighter but also capable of adapting to their environment. As research continues, we can expect to see ceramics playing a growing role in renewable energy applications—such as in efficient solar panels and energy storage systems—and in the electronics sector, where enhanced thermal management and electrical insulation are increasingly critical. This evolution points toward a future where ceramics are integral to high-performance, sustainable technologies across multiple industries.

Challenges and Innovations

Despite the promising advancements, the ceramic industry faces several challenges that need to be addressed. One of the primary hurdles is the complexity of ceramic manufacturing, which often involves energy-intensive processes and precise control over microstructures to achieve the desired performance. Integrating ceramics into new applications requires overcoming issues related to brittleness and scalability. Ongoing research and development efforts are paving the way for innovative solutions—ranging from advanced fabrication techniques to the development of hybrid materials that combine ceramics with polymers or metals. These innovations are poised to reshape the ceramic industry, making it more adaptable, cost-effective, and aligned with the demands of tomorrow’s technological landscape

The Power of Ceramics: High-Tech Applications Across Industries

Ceramics are used extensively across many industries due to their high resistance to heat, wear, and corrosion. Their thermal insulation and electrical resistance make them essential in aerospace, automotive, and electronics applications. These materials can withstand very high temperatures, making them ideal for extreme environments.

In the automotive industry, ceramic materials are used in engine components, brake pads, and catalytic converters. Their low density and wear resistance help improve fuel efficiency and vehicle longevity. Applications in the automotive industry include coatings and insulators that enhance performance and safety.

The electronics industry relies on advanced technical ceramics for circuit boards, battery components, and high-tech smartphone screens. Ceramics are also used in Apple’s Ceramic Shield, offering scratch resistance and durability. Used in many consumer and industrial applications, these materials provide thermal conductivity and electrical insulation for cutting-edge technology.

In aerospace applications, technical ceramics are found in rocket nozzles, heat shields, and jet engines due to their refractory and high-temperature resistance properties. Ceramics are also used in space exploration, reducing heat damage and improving reusability. Their corrosion resistance and mechanical properties make them essential for high-performance aerospace components.

As industries move towards sustainability, ceramic materials are used to develop energy-efficient, recyclable solutions. From solar panels to fuel cells, ceramics support eco-friendly innovations across different industries. Their ability to withstand extreme conditions while enhancing performance makes ceramics a key material for the future.

Purchase the Best Types of Ceramics and Porcelain Tiles at Ramirro Ceramica

Shop Now | Chat With Expert | View Catalogue

At Ramirro Ceramica, you can purchase the best types of ceramic tiles and porcelain tiles both online and offline. Our wide collection includes high-tech ceramics and advanced ceramic materials that are typically used in applications across various industries. Our range of materials is designed to meet different needs, with ceramics made for cutting tools, industrial components, and products that require desirable properties such as low density, wear resistance, and the ability to withstand very high temperatures. Materials like ceramic tiles are perfect for both residential and industrial settings, with interesting applications in flooring, walls, and other areas. Whether you need ceramic tiles for luxury projects or materials used in applications requiring durable and long-lasting performance, we have the perfect solution. For more information or to explore our products, don’t hesitate to contact us online or visit our showroom!

References/Further Reading

History of Ceramics Tiles: From Pottery to Modern…

Vitrified Porcelain vs Ceramic Tiles: What’s the Difference?

Ceramic Tiles Market | Find Best Tiles Exporting Countries…

6577+ Best Tile Designs in North America | Shop Ceramic…

Red Sea Crisis: The Impact on India’s Tile Market and…

Tiles in United States of America | Buy Ceramic & Porcelain…

Top 10 Countries Benefiting from Indian Tile Imports

5210+ Best Design Tiles In Seoul South Korea

3+ Innovative Recycled Plastic Tile Products & Alternatives

Best Extreme Weatherproof Tiles > Heat, Acid, Fire, Slip…

Why Should You Trust us?

Here’s what you get out of our article. Our team have various Ceramic Experts with experience of more than 25 Years, researches on problems our customer faces in tiling industry.

Ramirro Ceramica, – One of The Leading Tiles Manufacturer and Supplier globally, helps you people gain knowledgeable insight before making your purchase decision for products related to the floor and wall tiles.

So, we have closely monitored all kinds of trends in the ceramic tiles manufacturing world, from the old days of clay and plain color to modern digital, realistic-looking designs printed on ceramics with high-depth effects.

Our tiling Experts have seen thousands of different tiles patterns, sizes, materials, pricing, and installation techniques throughout their career.

Their expertise shared with you in simplified and organised way, helps you choose and make better decision before purchasing any flooring option available in market.

Brief about Company:

Ramirro is one of the finest Tiles manufacturers in India manufacturing porcelain and ceramic tiles. Our products have a variety of sizes and types of tiles ranging from Ceramics, porcelain, Full body etc. This helps you choose the perfect fit for your project. Plus, our collection will help you get inspiration from the architect’s design.

Here’s some more helpful links that showcase our users trust on Ramirro Ceramica Brand:

– Growth in International Market

– Trusted and Licensed Exporter

– Manufacturing Plant in India

Here’s our social proof by LinkedIn competing with top known global tiling brands: