When it comes to selecting the best thermal flooring materials and techniques for hot and cold weather, understanding how different climates affect flooring performance is crucial. Proper thermal flooring solutions not only improve comfort but also enhance energy efficiency and longevity. Ramirro Ceramica, a leader in innovative and high quality tile manufacturing, specializes in climate adapted flooring materials designed to withstand extreme temperatures. Whether dealing with freezing winters or scorching summers, using the right materials and installation methods ensures your floors remain durable, efficient, and stylish. In this article, we explore the top thermal flooring materials and proven installation techniques that deliver optimal results in both hot and cold weather conditions.

- Climate Responsive Flooring for Modern Spaces

- Understanding Thermal Flooring: Why It Matters in Hot and Cold Climates

- Understanding Thermal Challenges in Flooring

- Best Thermal Flooring Materials for Extreme Climates

- Advanced Tile Installation Techniques for Cold Climates

- Advanced Tile Installation Techniques for Hot Climates

- Universal Thermal Management Techniques

- Country Specific Engineering & Architectural Applications

- Why Choose Ramirro Ceramica for Thermal Flooring Solutions

- Invest in the Right Thermal Flooring with Ramirro Ceramica

Climate Responsive Flooring for Modern Spaces

Temperature fluctuations in hot and cold climates introduce significant challenges for flooring materials. Expansion and contraction caused by heat and cold can lead to cracks, warping, and adhesive failures if not properly addressed. Thermal flooring materials combined with advanced installation techniques offer effective solutions to maintain comfort, improve energy efficiency, and ensure long lasting durability. Ramirro Ceramica stands out as a provider of premium, climate resilient tiles designed specifically to perform in diverse temperature conditions. Their range of innovative products and expert installation practices supports architects, engineers, and homeowners in creating floors that withstand extreme temperatures while enhancing indoor comfort and sustainability.

Understanding Thermal Flooring: Why It Matters in Hot and Cold Climates

Thermal flooring means choosing materials that can handle changes in temperature without damage and keep indoor spaces comfortable. Some materials also have thermal mass, which means they can absorb heat, store it, and release it slowly keeping floors cooler in summer and warmer in winter.

When temperatures rise and fall, floors expand and contract. Without the right materials, this can lead to cracks, weak bonding, or freeze thaw damage.

In colder regions, radiant heated floors are often combined with tiles like porcelain. Since tiles conduct heat well, they spread warmth evenly, reduce energy use, and improve comfort.

Simply put: thermal flooring helps your space stay durable, efficient, and comfortable in both hot and cold climates.

Understanding Thermal Challenges in Flooring

Hot Climate Challenges

Rapid Drying of Adhesives and Grouts: High temperatures cause adhesives and grouts to dry too quickly, which can lead to weak initial bonds. This premature drying prevents the materials from properly adhering to the substrate and tiles, risking later detachment or surface failure.

Tile Surface Overheating and Expansion: Exposure to intense sunlight and heat causes tiles to expand, sometimes unevenly. This thermal expansion puts stress on the tile joints and adhesives, which can result in cracks, warping, or buckling if proper expansion gaps or flexible adhesives aren’t used.

Weak Initial Bonding Due to Dry Substrates: Dry, hot substrates absorb moisture rapidly from the adhesive, leading to insufficient curing and compromised bonding. Pre wetting substrates and using polymer modified adhesives are common solutions to maintain bond integrity.

Cold Climate Challenges

Delayed Curing of Mortars and Adhesives: Low temperatures slow down the chemical reactions needed for adhesives and mortars to cure and set properly. This can delay project timelines and weaken the bond strength if cold weather conditions aren’t mitigated during installation.

Freezing Risks in Bonding Materials: If adhesives or mortars freeze before fully setting, the crystallization process disrupts bond formation, permanently damaging the installation. Controlled environment and fast setting mortars designed for cold applications help prevent this.

Freeze Thaw Cycle Cracks in Tiles: Moisture that penetrates tiles or grout can freeze and expand during cold cycles, causing physical damage such as cracks or surface delamination. Using low water absorption tiles like porcelain and applying proper sealants greatly reduces these risks.

Best Thermal Flooring Materials for Extreme Climates

Porcelain Tiles (Low Water Absorption)

Porcelain tiles are highly suitable for extreme climates due to their low water absorption rate. This makes them resistant to damage caused by freeze thaw cycles common in cold weather.

These tiles are dense and durable, offering excellent thermal stability which means they maintain structural integrity despite temperature fluctuations.

Their resistance to moisture penetration reduces the risk of cracking or warping, making them ideal for both hot and cold environments.

Natural Stone with Proper Sealing

Natural stone such as granite, marble, and slate exhibits high thermal conductivity, making it an excellent choice for floors with heated systems in colder climates. It efficiently stores and radiates heat, enhancing energy efficiency and indoor comfort.

However, natural stone is porous and requires proper sealing to prevent water absorption that could lead to freeze thaw damage or staining, especially important in wet or cold climates.

When sealed correctly, natural stone combines durability with luxury aesthetics and performs well under extreme temperature conditions.

-

DOVE – Grey Full Body Tiles

DOVE – Grey Full Body Tiles -

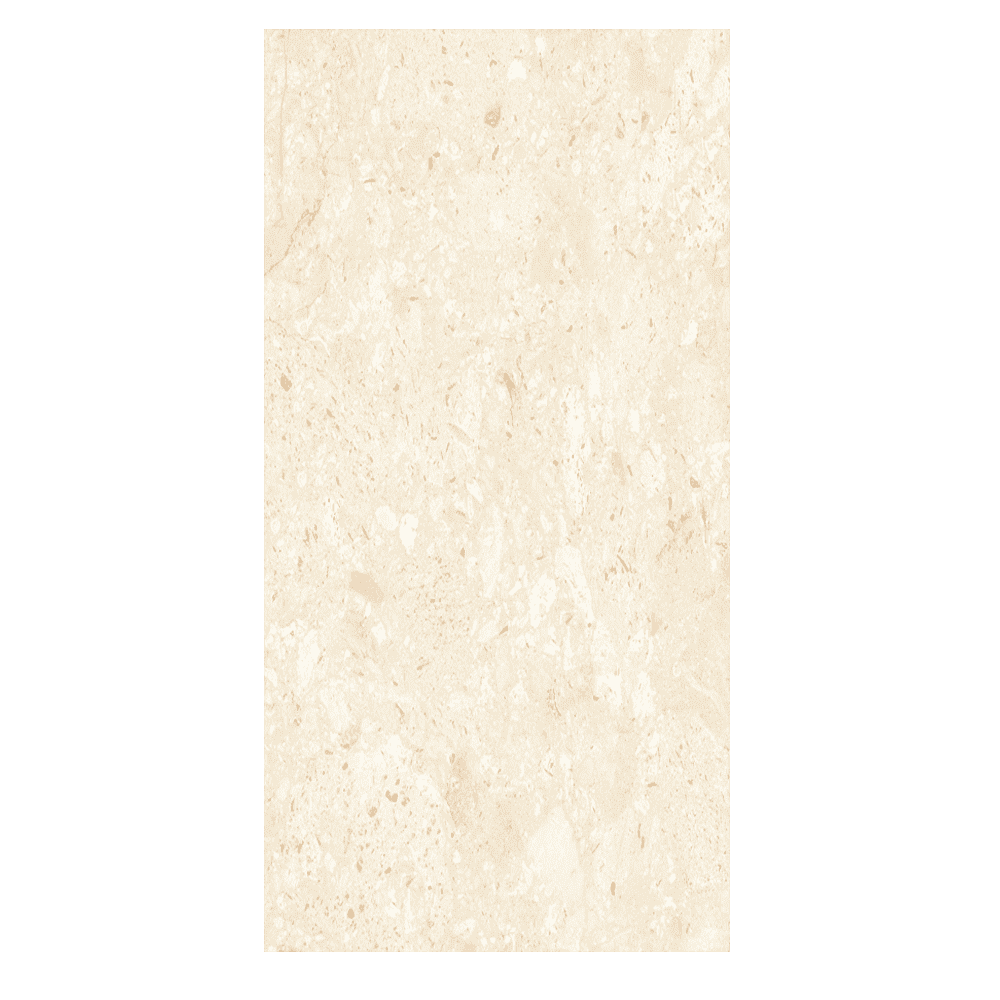

TERRAZZO BEIGE Marble Tile Design for Porcelain

TERRAZZO BEIGE Marble Tile Design for Porcelain -

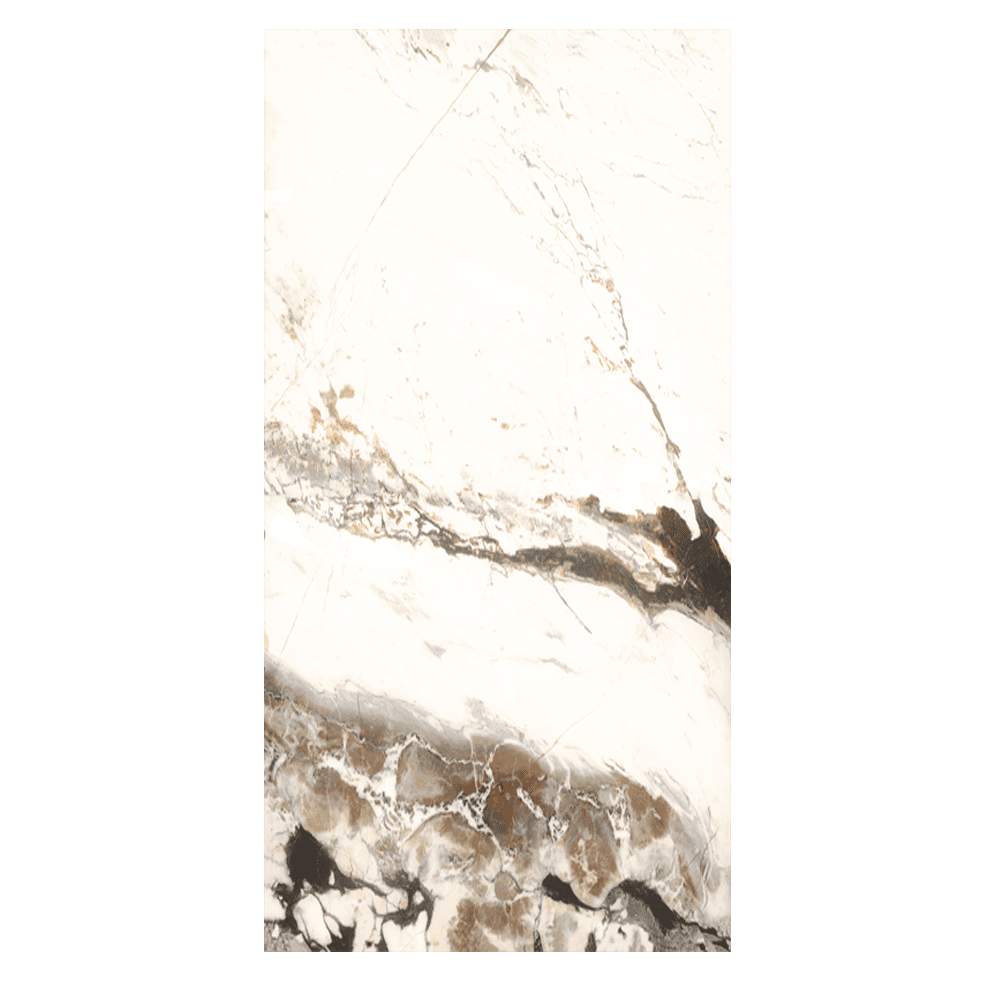

TROPICANA WHITE Marble Tile Design for Porcelain

TROPICANA WHITE Marble Tile Design for Porcelain -

WILLIAM GREY Marble Tile Design for Porcelain

WILLIAM GREY Marble Tile Design for Porcelain -

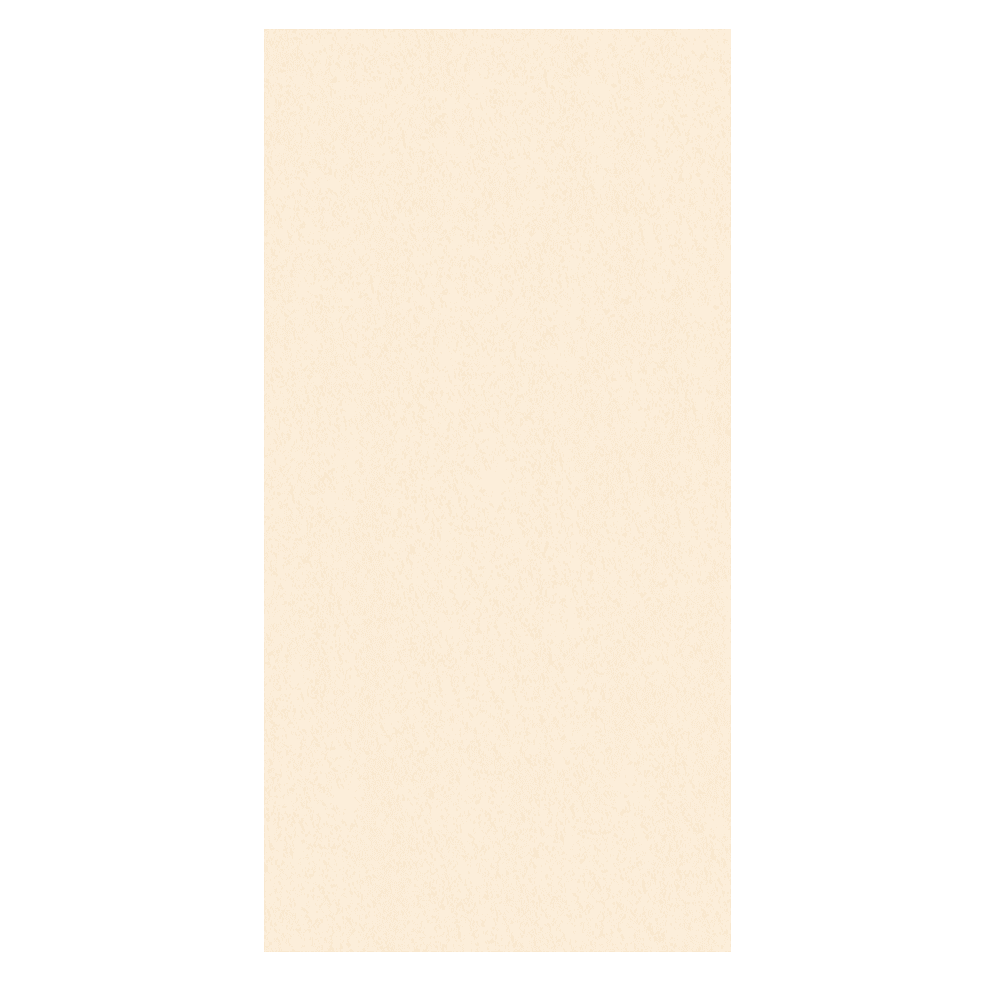

TROPICANA CREMA Marble Tile Design for Porcelain

TROPICANA CREMA Marble Tile Design for Porcelain -

TRAVENTINO ROYAL Marble Tile Design for Porcelain

TRAVENTINO ROYAL Marble Tile Design for Porcelain -

STATUARIO PEARL Marble Tile Design for Porcelain

STATUARIO PEARL Marble Tile Design for Porcelain -

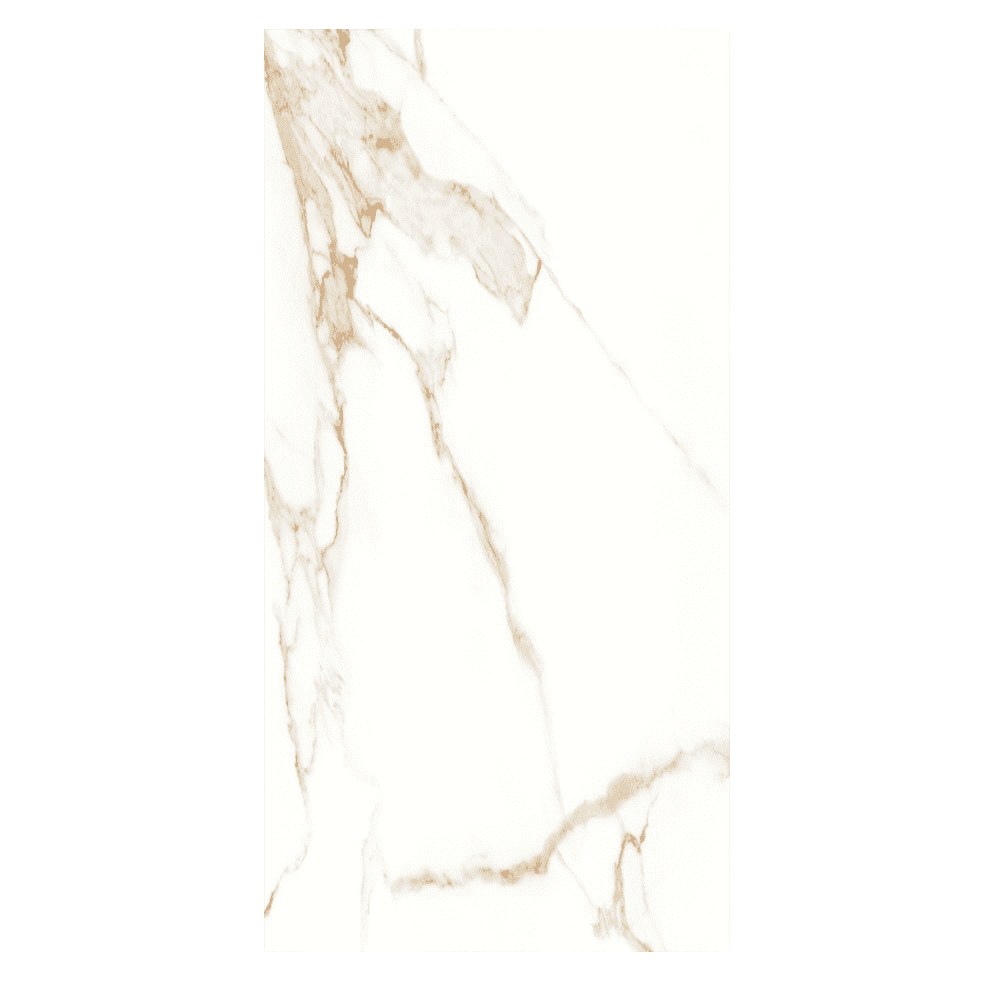

STATUARIO GOLD Marble Tile Design for Porcelain

STATUARIO GOLD Marble Tile Design for Porcelain -

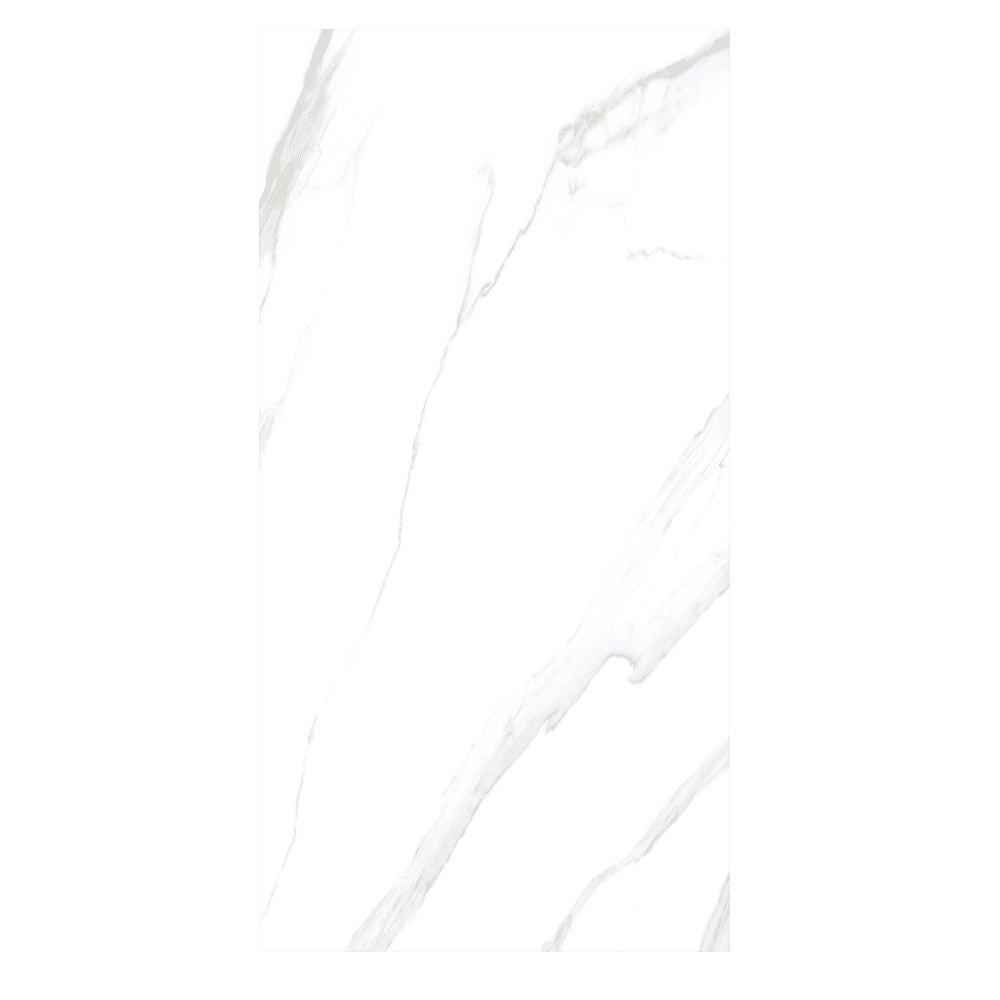

SEAMLESS STATUARIO Marble Tile Design for Porcelain

SEAMLESS STATUARIO Marble Tile Design for Porcelain -

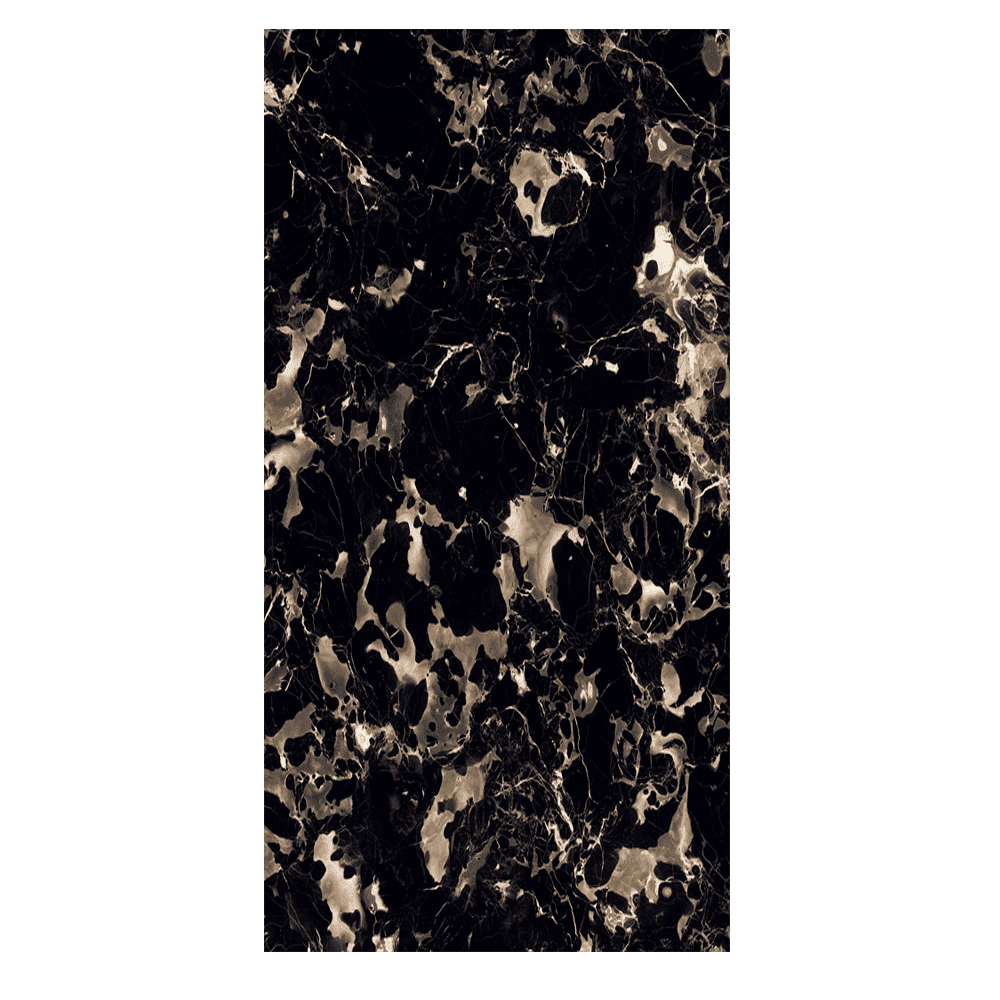

PORTORO BLACK Marble Tile Design for Porcelain

PORTORO BLACK Marble Tile Design for Porcelain -

NOVANA GREY Marble Tile Design for Porcelain

NOVANA GREY Marble Tile Design for Porcelain -

NOVANA BEIGE

NOVANA BEIGE -

MARMI BRECCIA Marble Tile Design for Porcelain

MARMI BRECCIA Marble Tile Design for Porcelain -

LEVIN NATURAL Marble Tile Design for Porcelain

LEVIN NATURAL Marble Tile Design for Porcelain -

FOREST GREEN Marble Tile Design for Porcelain

FOREST GREEN Marble Tile Design for Porcelain -

DYNO ROYAL Marble Design Slab Tiles

DYNO ROYAL Marble Design Slab Tiles -

DANISH CREAM Marble Tile Design for Porcelain

DANISH CREAM Marble Tile Design for Porcelain -

CRYSTAL ONYX Marble Tile Design for Porcelain

CRYSTAL ONYX Marble Tile Design for Porcelain

Advanced Tile Installation Techniques for Cold Climates

Controlled Temperature Installations

Use heated enclosures, tents, or temporary shelters equipped with heaters to maintain ideal working temperatures (50-80°F) during tile installation. This prevents mortar and adhesives from freezing or curing too slowly in cold weather.

Monitoring substrate and ambient temperatures with infrared thermometers ensures the floor and surroundings remain within recommended ranges for proper bonding and curing.

Protect the installation area with insulated blankets or polyethylene sheets after laying tiles to retain warmth during curing.

Polymer Modified Mortars

Polymer modified mortars contain additives that enhance adhesion and flexibility, which improves bond strength in cold conditions.

These mortars cure faster at low temperatures compared to traditional options, reducing project delays and exposure to damaging freeze thaw cycles.

Use fast set polymer mortars that achieve initial cure rapidly, enabling earlier foot traffic and finishing.

Low Water Absorption Tiles

Selecting tiles with low water absorption, such as porcelain, is essential for durability in snow prone and freeze thaw zones.

These tiles resist moisture infiltration, preventing cracks caused by water freezing and expanding inside the tile structure.

Low porosity also limits surface staining and weathering in harsh climates.

Vapor Barriers

Installing vapor barriers beneath the tile system prevents moisture migration from subfloors into the tile and mortar layers.

This reduces condensation risk, mold growth, and freeze related damage to the installation.

Proper vapor barrier selection and placement according to substrate and climate conditions are crucial for long term flooring performance.

Advanced Tile Installation Techniques for Hot Climates

Cooling & Shading Methods

Store tile adhesives, mortars, and grout bags in shaded or air conditioned spaces for at least 24 hours before use to prevent premature setting caused by heat exposure.

Mix mortars using cool or even ice chilled water to extend working times and avoid rapid drying on hot days.

Pre wet tile surfaces before grouting to maintain adequate moisture, preventing grout from drying out too quickly and compromising bond strength.

Perform outdoor installations in early morning or late evening to avoid peak heat periods and direct sunlight. Use tarps or temporary shades to protect work surfaces and materials during the day.

Modified Mortars with Longer Open Time

Use polymer modified or specialized adhesives that offer longer open and working times, allowing installers more flexibility to work in hot conditions without adhesive skinning prematurely.

Mortars with improved deformability accommodate thermal expansion and contraction caused by heat, reducing the risk of tile debonding and cracking.

Expansion Joint Design

Design and install expansion joints strategically to accommodate tile and substrate movement due to heat induced surface expansion.

Properly placed joints minimize stress concentration, preventing tile cracking and maintaining installation integrity through thermal cycles.

Universal Thermal Management Techniques

False Flooring Systems (Czech Republic & Beyond)

Raised access floors create an air gap between the original floor and the final surface, providing thermal buffering that reduces heat transfer and controls moisture buildup.

This system is widely used in data centers, office buildings, and regions with high humidity where thermal and moisture management is critical.

The air gap facilitates circulation of conditioned air and simplifies maintenance by allowing easy access to cables and utilities beneath the floor.

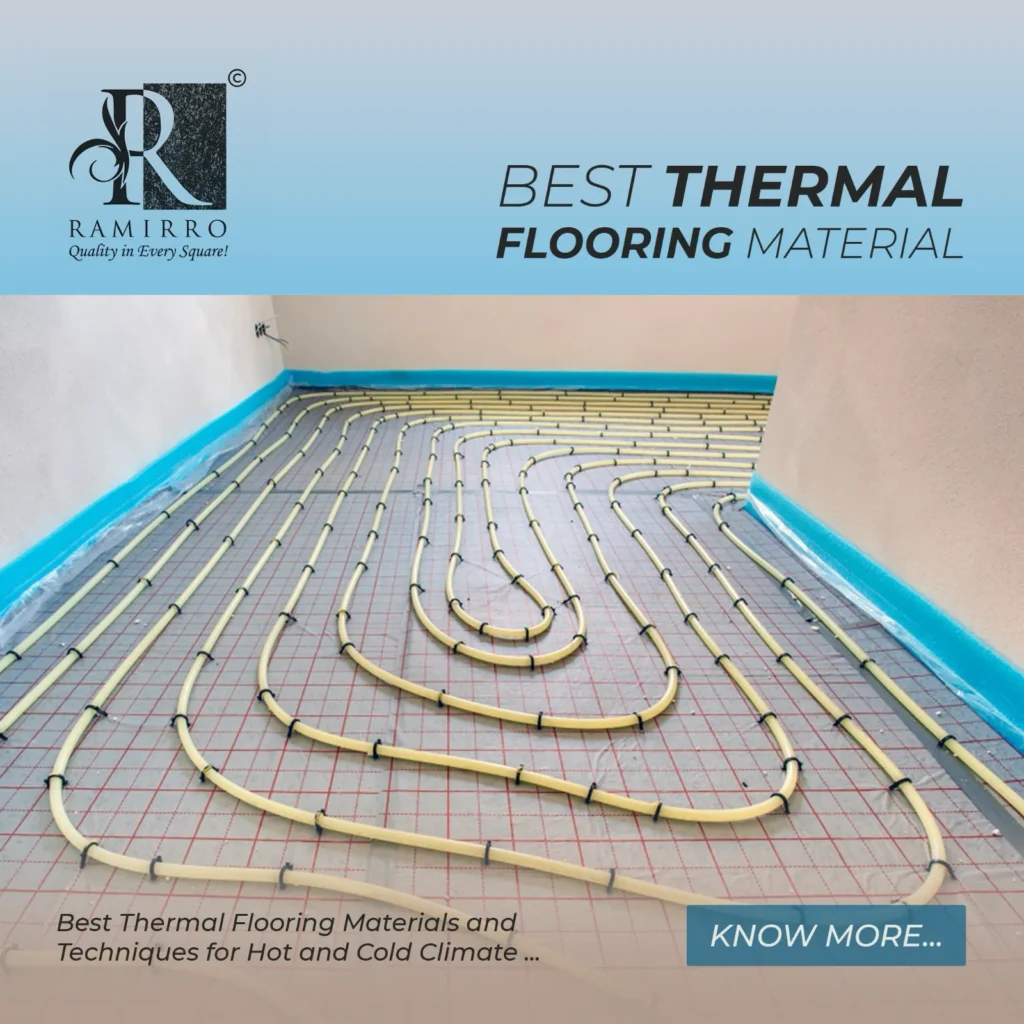

Heated Floor Systems for Cold Weather

Electric radiant heating systems are popular for retrofit projects due to their easy installation under existing floors.

Hydronic radiant heating uses heated water circulated through pipes beneath floors, ideal for larger buildings requiring efficient, uniform heat distribution.

These systems offer energy efficient heating by delivering warmth directly to the floor surface, reducing overall energy consumption compared to traditional heating methods.

Underfloor Heating Integration with Tiles

Porcelain tiles are excellent heat conductors, making them ideal for use with radiant heating systems. Porcelain tiles have high thermal conductivity compared to other flooring materials like carpet or hardwood, which act as insulators and slow down heat transfer. Their dense composition allows them to efficiently transfer heat from underlying heating elements to the room above, creating consistent warmth throughout the space. The compact structure derived from pressing and firing at high temperatures (often above 2,200°F) guarantees optimal thermal conductivity.

Thermal Breaks in Flooring Systems

Thermal breaks, typically made from expanded polystyrene (EPS) or polyurethane (PU) foam, are installed within floor slabs or between floors and walls.

These barriers reduce unwanted heat loss, improving overall building thermal efficiency.

Incorporating thermal breaks helps minimize energy consumption and contributes to sustainable building design.

Sealing Outdoor Tiles Against Freeze Thaw Damage

High quality sealants applied to tiles and grout prevent water penetration that can cause cracking during freeze thaw cycles.

Regular reapplication of sealant maintains protection and extends the longevity of exterior tile installations exposed to harsh climates.

Proper sealing is essential for preserving both the functionality and appearance of outdoor tiled surfaces.

Addressing Thermal Shock in Tile Installations

Expansion joints allow for accommodation of tile and substrate movement caused by rapid temperature changes, preventing cracking and structural damage.

Using tiles with low thermal expansion coefficients reduces stress induced by temperature fluctuations.

Regular inspection of tiled surfaces helps detect early signs of thermal stress, enabling timely maintenance and repair.

Country Specific Engineering & Architectural Applications

Cold Regions (Canada, Northern Europe)

Use of vapor barriers beneath flooring prevents moisture migration, crucial in cold climates where condensation can damage materials.

Heated floor systems, including radiant electric and hydronic heating, provide efficient warmth in freezing temperatures, improving comfort and energy use.

Porcelain tiles are preferred for their low water absorption, durability, and resistance to freeze thaw cycles common in these regions.

Hot Regions (Middle East, India, Gulf)

Expansion joints are essential to accommodate thermal movement caused by extreme heat and sun exposure, preventing tile cracking and warping.

False flooring systems help manage internal building temperatures by providing an air gap for cooled air circulation and service access.

Proper shaded storage of materials during installation preserves adhesive and grout integrity, essential for hot climate success.

Mixed Climates (Czech Republic, USA, Japan)

Raised flooring is widely used for both cable management and thermal buffering, balancing heating and cooling demands in variable climates.

Thermal breaks, such as EPS or PU foam layers, are integrated into slabs and walls to minimize heat loss and improve overall energy efficiency.

Polymer modified mortars are commonly utilized to provide strong, flexible bonds resilient to temperature variations typical of mixed climate zones.

Why Choose Ramirro Ceramica for Thermal Flooring Solutions

Ramirro Ceramica specializes in high quality porcelain tiles engineered specifically for optimal thermal management in extreme climates.

Their materials are designed to withstand temperature fluctuations, moisture, and freeze thaw cycles, ensuring long lasting performance and structural integrity.

Trusted by architects and engineers worldwide, Ramirro Ceramica delivers solutions that combine modern aesthetics with superior durability.

The company is committed to sustainable production processes, aligning with eco friendly building standards and promoting energy efficient flooring solutions.

Invest in the Right Thermal Flooring with Ramirro Ceramica

Choosing the right thermal flooring means combining the best flooring materials with proven installation techniques. From radiant floor heating systems that improve comfort to porcelain tile floors designed to handle temperature fluctuations, every detail matters. The right surface materials not only maintain ideal floor surface temperature but also support a healthier indoor environment and better indoor air quality.

At Ramirro Ceramica, we provide climate ready flooring solutions trusted by architects and engineers worldwide. Whether it’s underfloor heating systems with efficient heating elements, or tiles engineered for both cooling and heating control systems, our products are built to deliver superior thermal performance. With modern aesthetics, durability, and sustainable design, Ramirro Ceramica tiles remain the best flooring choice for projects in hot, cold, or mixed climates.

Contact Ramirro Ceramica today to explore custom thermal flooring solutions tailored to your project’s climate and performance needs.

Shop Now | Chat With Expert | View Catalogue

Why Should You Trust us?

Here’s what you get out of our article. Our team have various Ceramic Experts with experience of more than 25 Years, researches on problems our customer faces in tiling industry.

Ramirro Ceramica, – One of The Leading Tiles Manufacturer and Supplier globally, helps you people gain knowledgeable insight before making your purchase decision for products related to the floor and wall tiles.

So, we have closely monitored all kinds of trends in the ceramic tiles manufacturing world, from the old days of clay and plain color to modern digital, realistic-looking designs printed on ceramics with high-depth effects.

Our tiling Experts have seen thousands of different tiles patterns, sizes, materials, pricing, and installation techniques throughout their career.

Their expertise shared with you in simplified and organised way, helps you choose and make better decision before purchasing any flooring option available in market.

Brief about Company:

Ramirro is one of the finest Tiles manufacturers in India manufacturing porcelain and ceramic tiles. Our products have a variety of sizes and types of tiles ranging from Ceramics, porcelain, Full body etc. This helps you choose the perfect fit for your project. Plus, our collection will help you get inspiration from the architect’s design.

Here’s some more helpful links that showcase our users trust on Ramirro Ceramica Brand:

– Growth in International Market

– Trusted and Licensed Exporter

– Manufacturing Plant in India

Here’s our social proof by LinkedIn competing with top known global tiling brands: