Australian Tile Standards for Porcelain and Ceramic Tile Installation (AS 3958.1 Guide)

Australia has some of the most rigorous tile standards in the world, shaped by local conditions such as heat, moisture, outdoor living, and high expectations for safety and durability. This guide explains Australian Tile Standards for Porcelain and Ceramic Tile Installation, with a clear focus on AS 3958.1, the Australian Standard that governs how tiles should be installed on walls and floors in both internal and external areas. This article explains how correct tile selection, installation methods, and supporting standards work together to reduce failure risks and improve long term performance. Ramirro Ceramica, an engineering focused tile manufacturer, aligns its porcelain and ceramic tile solutions with Australian standards to support safer, more reliable outcomes across residential and commercial projects.

- Australian Tile Standards for Porcelain and Ceramic Tile Installation (AS 3958.1 Guide)

- Why Australia Has Some of the Strictest Tile Standards in the World

- How Australian Tile Standards Work Together (The Compliance Framework)

- Inside AS 3958.1: How a Compliant Installation Is Built

- Slip Resistance in Australia: AS 4586 and P‑Ratings Explained

- Choosing the Right Tile: AS 3958.2 and AS ISO 13006 in Practice

- Wet Area and External Tiling: AS 3740 and AS 4654

- Testing, Tolerances and “CC Compliant” Tiles

- How Australians Actually Use Porcelain and Ceramic Tiles

- Checklist: Specifying Ramirro Ceramica Tiles to Meet Australian Standards

- Australian Tile Standards: Where Safety, Performance, and Accountability Finally Meet

Why Australia Has Some of the Strictest Tile Standards in the World

Australia’s brutal sun, salty coastal winds, and obsession with indoor outdoor living make tile failures like cracking under heat expansion or slipping on wet patios not just ugly, but dangerous and costly. Unlike milder climates elsewhere, tile performance matters more here because heat, UV exposure, coastal salt air, wet bathrooms, and that endless outdoor culture demand materials and methods that endure without leaking, debonding, or creating trip hazards.

Australian Tile Standards aren’t about stifling design; they’re laser focused on safety, durability, moisture control, and liability protection for homeowners, builders, and insurers. In simple terms: Australian tile standards exist to protect people, buildings, and builders not just tiles.

How Australian Tile Standards Work Together (The Compliance Framework)

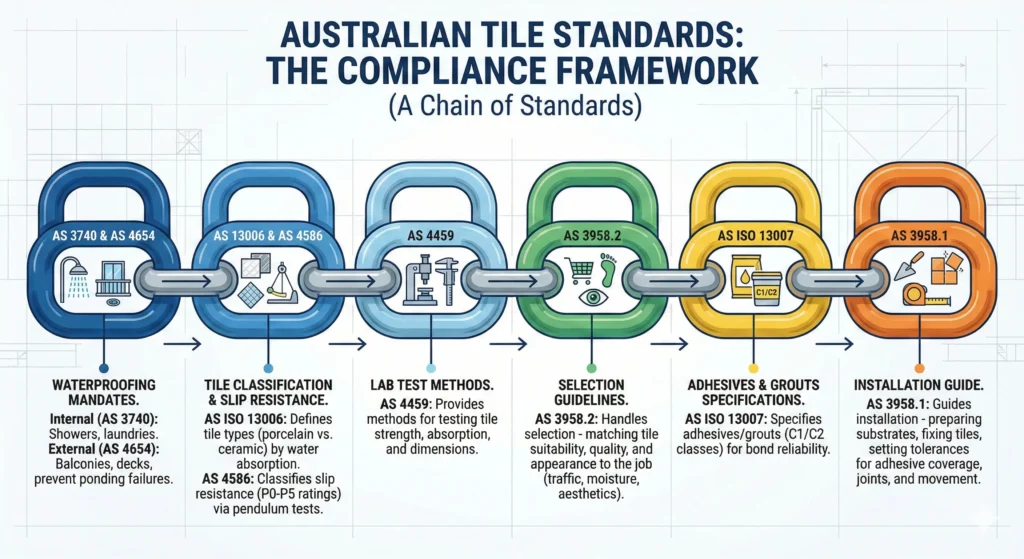

Think of it as a chain:

AS 3958.1 guides installation – preparing substrates, fixing tiles on walls/floors indoors/outdoors (even pools), and setting tolerances for adhesive coverage, joints, and movement.

AS 3958.2 handles selection – matching tile suitability, quality, and appearance to the job (traffic, moisture, aesthetics).

AS 4586 classifies slip resistance (P0-P5 ratings) for new surfaces via pendulum tests.

AS 4459 provides lab test methods for tile strength, absorption, and dimensions.

AS 3740 mandates internal wet area waterproofing (showers, laundries) before tiling.

AS 4654 covers external waterproofing (balconies, decks) to prevent ponding failures.

AS ISO 13006 defines tile classifications (porcelain vs ceramic by water absorption).

AS ISO 13007 specifies adhesives/grouts (C1/C2 classes) for bond reliability.

From Factory to Floor (Visual Idea)

Factory (AS 4459 + ISO 13006 testing) → Selection (AS 3958.2) → Prep/Waterproof (AS 3740/4654) → Install (AS 3958.1 + ISO 13007) → Safety Check (AS 4586).

Inside AS 3958.1: How a Compliant Installation Is Built

Guide to Installation

AS 3958.1 isn’t a step by step DIY manual, it’s the professional blueprint for installing porcelain and ceramic tiles on walls, floors, and mosaics across internal, external areas, and even pools, focusing on background preparation, fixing, and grouting with strict criteria for tolerances, coverage, and joints.

Substrate and Surface Flatness

A “suitable substrate” must be structurally sound, clean, dry, and flat within specified tolerances; no excessive deflection, contamination, or poor screeds allowed, as these cause lippage (uneven tile heights) and debonding failures.

Adhesive Coverage and Bonding

Expect 90-100% coverage on wet area and external floors (no edge voids), with walls at 90% minimum; pair with AS ISO 13007 classes like C1 (basic) or C2 (improved) adhesives to ensure bonds hold under Australia’s heat and moisture.

Grout Joints, Lippage and Tile Tolerances

AS 3958.1 demands consistent joint widths and minimal lippage, critical for large rectified porcelain; tolerances from AS 4459 (warpage, size variation) dictate wider joints (e.g., 3mm minimum) to hide manufacturing realities.

Movement Joints and Stress Management

Place them at perimeters, around columns, over structural joints, and every 5-6m in large areas; use flexible sealants or profiles (never rigid grout) to absorb expansion from heat/UV without cracking.

Slip Resistance in Australia: AS 4586 and P‑Ratings Explained

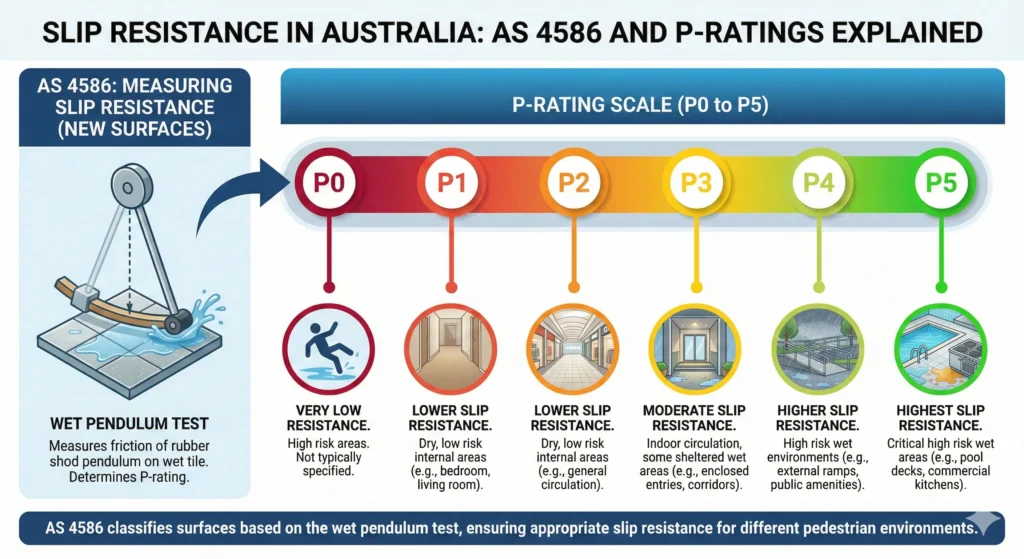

What AS 4586 Actually Measures

AS 4586 is the Australian Standard used to classify the slip resistance of new pedestrian surfaces. It applies to tiles used in residential, commercial, and public spaces where foot traffic is expected.

Slip resistance is commonly measured using the wet pendulum test, where a rubber shod pendulum swings across a wet tile surface. The level of friction measured during this test determines the tile’s P-rating, ranging from P0 to P5.

P‑Ratings from P0 to P5 (Clarifying P1, P2, P3)

P1 and P2 indicate lower slip resistance and are generally limited to dry, low risk internal areas.

P3 provides moderate slip resistance and is commonly used in indoor circulation spaces and some sheltered wet areas.

P4 and P5 offer higher slip resistance and are typically required in high risk wet environments, such as pool surrounds, ramps, and commercial kitchens.

Higher P-ratings improve safety but may affect cleaning and appearance, so selection should match the intended use.

Matching Slip Rating to Real Spaces

| Space | Minimum P-Rating | Example |

|---|---|---|

| Living rooms (dry) | P1-P2 | Smooth porcelain |

| Bathrooms | P3-P4 | Textured ceramic |

| Pool edges | P4-P5 | Structured porcelain |

| Retail entries | P4 | Anti slip finishes |

Choosing the Right Tile: AS 3958.2 and AS ISO 13006 in Practice

How AS 3958.2 Guides Tile Selection

AS 3958.2 supports correct tile selection by matching tile properties to traffic levels, moisture exposure, and environmental conditions, rather than appearance alone. It helps specifiers decide whether a tile is suitable for walls, floors, wet areas, or outdoor use.

Key factors considered include water absorption, surface finish, expected loads, and location, which influence whether porcelain or ceramic tiles are appropriate for a specific application.

What AS ISO 13006 Tells You About Porcelain vs Ceramic

AS ISO 13006 classifies ceramic tiles based on water absorption and manufacturing method, clearly distinguishing dense porcelain tiles from more absorbent ceramic tiles.

In Australian applications, low absorption porcelain tiles are commonly used for façades, outdoor areas, wet zones, and high traffic floors, while glazed ceramic tiles are typically specified for interior walls and lighter duty applications.

Thickness, Size and Australian Preferences

Most interior wall and floor tiles used in Australia fall within a typical thickness range of around 8-10 mm, with thicker formats often selected for external or higher load applications. Tile thickness must suit the intended use and substrate conditions.

Current Australian trends favour larger tile formats, rectified edges, neutral colours, and stone or concrete look finishes, combining clean aesthetics with practical performance.

Wet Area and External Tiling: AS 3740 and AS 4654

Waterproofing Internal Wet Areas (AS 3740)

AS 3740 sets the requirements for waterproofing internal wet areas such as bathrooms, showers, and laundries. It ensures moisture is properly contained within these spaces to protect surrounding structures.

Waterproofing must be completed and compliant before tiling begins. Tiles and grout are not waterproof, so installations under AS 3958.1 rely on AS 3740-compliant membranes for long term performance.

Waterproofing External Areas (AS 4654)

AS 4654 applies to external above ground areas including balconies, decks, and roof terraces. It addresses drainage, membrane selection, and exposure to weather conditions.

When AS 4654 and AS 3958.1 are not jointly followed, common failures include ponding water, membrane damage, and tile debonding. Correct coordination between waterproofing and tiling standards is essential for durable external installations.

Testing, Tolerances and “CC Compliant” Tiles

AS 4459 Test Methods

AS 4459 is a set of laboratory test methods used to measure tile properties such as breaking strength, water absorption, abrasion resistance, and dimensional accuracy. These tests provide objective data on how a tile is expected to perform.

For specifiers and regulators, AS 4459 test results confirm that a tile meets its declared classification under AS ISO 13006, rather than relying on visual appearance or marketing claims.

Size Tolerances and Flatness Expectations

All tiles are manufactured within defined size tolerances. Factors such as warpage and bowing become more noticeable with large format tiles, making realistic expectations essential.

AS 3958.1 sets limits for acceptable lippage, but compliance depends on proper joint widths, substrate flatness, and installation quality. Manufacturer technical bulletins help align tile tolerances with installation conditions.

Certification, Compliance Marks and Ramirro Ceramica’s Position

Australian projects commonly rely on test reports and compliance certificates demonstrating alignment with standards such as AS 4586 and AS ISO 13006. These documents support specification, approvals, and inspections.

Ramirro Ceramica provides transparent technical information, including tile thickness, slip ratings, and classifications, to help designers and builders assess compliance efficiently and with confidence.

How Australians Actually Use Porcelain and Ceramic Tiles

Typical Residential and Commercial Patterns

Porcelain dominates open plan living floors, outdoor patios, and high traffic commercial zones (cafes, offices) for its durability against heat, spills, and footfall.

Ceramic wall tiles shine in bathrooms, kitchens, and feature walls, valued for easy installation and moisture resistance in daily use areas. Busy families opt for easy clean matte finishes and low maintenance epoxy grouts that shrug off stains and scrubbing.

Colour, Finish and Thickness Choices

| Aspect | Common Australian Preference | Practical Reason |

|---|---|---|

| Colour & Look | Light neutrals, stone look, terrazzo look, concrete look | Helps manage heat, hides wear, suits modern and traditional interiors |

| Finish – Dry Areas | Polished finishes | Smooth appearance suitable for dry internal spaces |

| Finish – Wet & Outdoor Areas | Honed or structured finishes | Improved slip resistance for safety in wet conditions |

| Tile Thickness (Interior) | Around 8-10 mm | Suitable for standard residential wall and floor applications |

| Tile Thickness (External / High Load) | Thicker tile formats | Better strength and durability for outdoor and high traffic use |

Checklist: Specifying Ramirro Ceramica Tiles to Meet Australian Standards

Confirm tile classification under AS ISO 13006, including whether the tile is porcelain or ceramic and its water absorption class for the intended application.

Check slip resistance ratings in accordance with AS 4586, ensuring the correct P-class is specified for each space, such as living areas, wet zones, or external surfaces.

Verify substrate suitability and waterproofing, confirming compliance with AS 3740 for internal wet areas or AS 4654 for external above ground areas before tiling begins.

Select compatible adhesives and grouts that meet AS ISO 13007 performance classes and are suitable for the tile type, substrate, and site conditions.

Plan movement joints and tolerances as required under AS 3958.1, including perimeter joints, intermediate joints, adhesive coverage, and acceptable lippage limits.

Review test reports and technical data, such as slip ratings, tile thickness, and dimensional tolerances, to support compliance and specification decisions.

Confirm installation aligns with site conditions, including traffic levels, moisture exposure, and environmental factors, rather than relying on appearance alone.

Australian Tile Standards: Where Safety, Performance, and Accountability Finally Meet

Australian tile standards bring safety, performance, and accountability together in construction projects from floor and wall tiles in homes to mosaic tiles around swimming pools ensuring every installation of ceramic tiles and porcelain tiles withstands real world stresses without compromise.

These Standards Australia guidelines cover everything from tile size tolerances to adhesive mix ratios, protecting against slips, leaks, and failures whether you’re tiling a coastal balcony or a high traffic lobby.

Ready to select with total confidence? Request Ramirro Ceramica’s technical information, tile classifications, and project specific suitability guidance today; get compliant, future proof solutions tailored to your build.

Shop Now | Chat With Expert | View Catalogue

Why Should You Trust us?

Here’s what you get out of our article. Our team have various Ceramic Experts with experience of more than 25 Years, researches on problems our customer faces in tiling industry.

Ramirro Ceramica, – One of The Leading Tiles Manufacturer and Supplier globally, helps you people gain knowledgeable insight before making your purchase decision for products related to the floor and wall tiles.

So, we have closely monitored all kinds of trends in the ceramic tiles manufacturing world, from the old days of clay and plain color to modern digital, realistic-looking designs printed on ceramics with high-depth effects.

Our tiling Experts have seen thousands of different tiles patterns, sizes, materials, pricing, and installation techniques throughout their career.

Their expertise shared with you in simplified and organised way, helps you choose and make better decision before purchasing any flooring option available in market.

Brief about Company:

Ramirro is one of the finest Tiles manufacturers in India manufacturing porcelain and ceramic tiles. Our products have a variety of sizes and types of tiles ranging from Ceramics, porcelain, Full body etc. This helps you choose the perfect fit for your project. Plus, our collection will help you get inspiration from the architect’s design.

Here’s some more helpful links that showcase our users trust on Ramirro Ceramica Brand:

– Growth in International Market

– Trusted and Licensed Exporter

– Manufacturing Plant in India

Here’s our social proof by LinkedIn competing with top known global tiling brands: