A modern kitchen needs to do more than look good; it must perform like a professional workspace that is safe, hygienic, and built to last. A chef grade, inspector ready kitchen design focuses on smart planning, durable materials, and surfaces that can handle heat, moisture, spills, and frequent cleaning without losing performance. Ramirro Ceramica is a global ceramic and porcelain tile manufacturer known for engineering tiles that support these real kitchen demands, offering low water absorption, easy to clean surfaces, and safety focused finishes. In this article, you’ll learn how Ramirro Ceramica tiles help create kitchen designs that work like professional kitchens and are ready to meet everyday use and inspection standards with confidence.

- What is a Chef Grade Kitchen?

- The “Chef Grade Kitchen” Mindset: What Professional Chefs Actually Need

- What Makes a Kitchen “Inspector Ready”? (Commercial Grade Standards)

- The Chef Grade + Inspector Ready Formula: Designed for Chefs, Approved by Inspectors

- How Ramirro Ceramica Tiles Are Engineered for Chef Grade Performance

- Kitchen Design Ideas That Achieve Chef Level Functionality

- Why Tiles Outperform Other Materials in Chef Grade Kitchens

- Bringing Commercial Grade Precision into Home Kitchen Design with Ramirro Ceramica

What is a Chef Grade Kitchen?

A chef grade kitchen is designed to function like a professional kitchen, even in a home setting. It prioritizes efficient workflow, safety, and durability, allowing cooking tasks to move smoothly from preparation to cooking and cleaning without obstruction. Every element; layout, surfaces, flooring, and wall finishes is chosen to handle heat, moisture, spills, and heavy daily use while remaining easy to clean and maintain.

Good kitchen design directly affects cooking speed and safety. Clear movement paths reduce unnecessary steps, slip resistant floors help prevent accidents, and hygienic, non porous surfaces make cleaning faster and more effective. These same design choices also influence inspection results, as inspectors look for kitchens that are safe, washable, and resistant to moisture and contamination.

The “Chef Grade Kitchen” Mindset: What Professional Chefs Actually Need

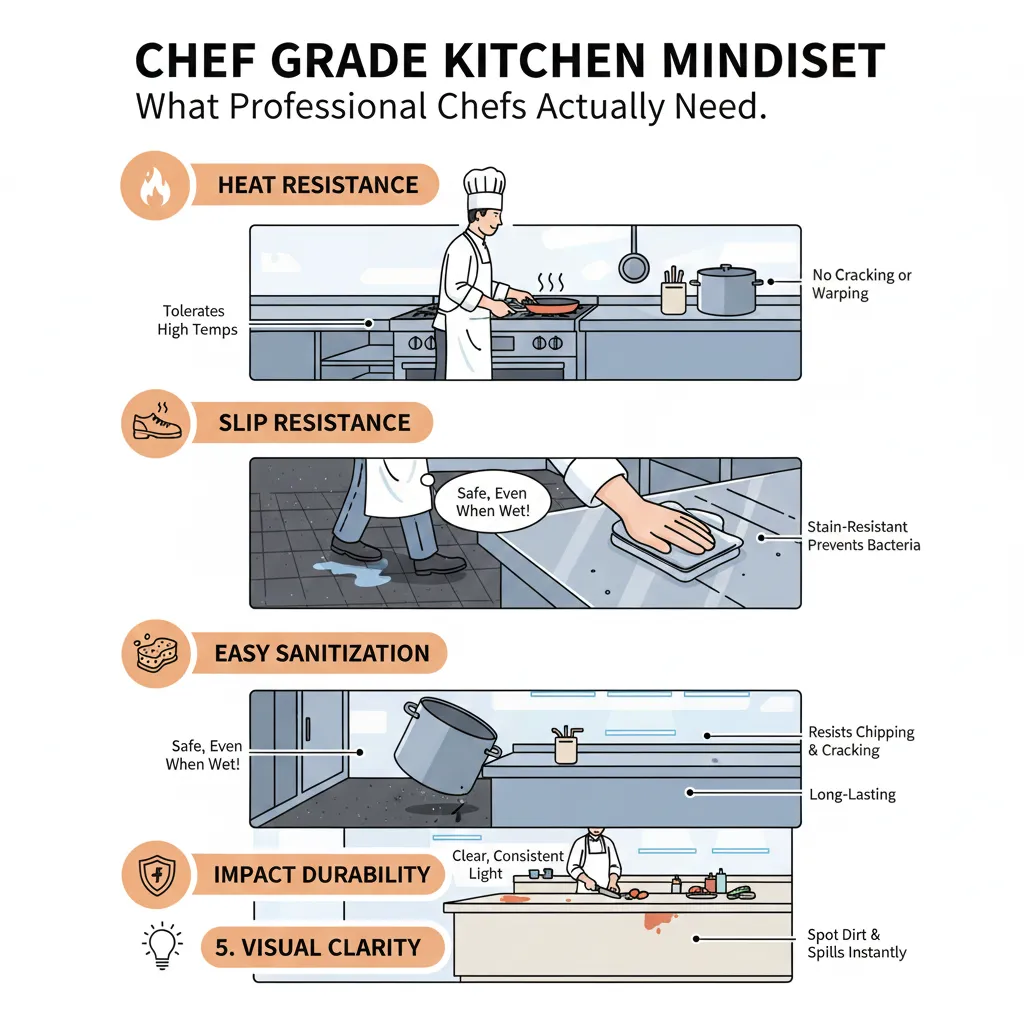

The 5 Chef Priorities That Shape Every Decision

Heat resistance

Cooking areas generate constant heat from burners, ovens, and hot utensils. Surfaces around stoves, prep counters, and backsplashes must tolerate high temperatures without cracking, discoloring, or warping. Heat resistant materials allow chefs to work faster and safer without worrying about surface damage.

Slip resistance

Professional kitchens are fast moving environments where spills are common. Floors in cooking and washing zones must provide grip even when wet or oily. Slip resistant surfaces reduce accidents, protect staff, and help kitchens meet safety checks.

Easy sanitization

Chefs need surfaces that can be cleaned quickly and thoroughly. Non porous, stain resistant materials prevent liquids, oils, and food particles from soaking in. This supports daily hygiene routines and reduces the risk of bacterial growth.

In busy kitchens, tools fall, pans hit surfaces, and equipment is moved frequently. Floors and wall surfaces must resist chipping, cracking, and surface damage so the kitchen remains functional and inspection ready over time.

Visual clarity

Good lighting and surface colors help chefs instantly spot spills, dirt, or cross contamination. Materials that maintain consistent color and finish improve cleanliness and reduce errors during service.

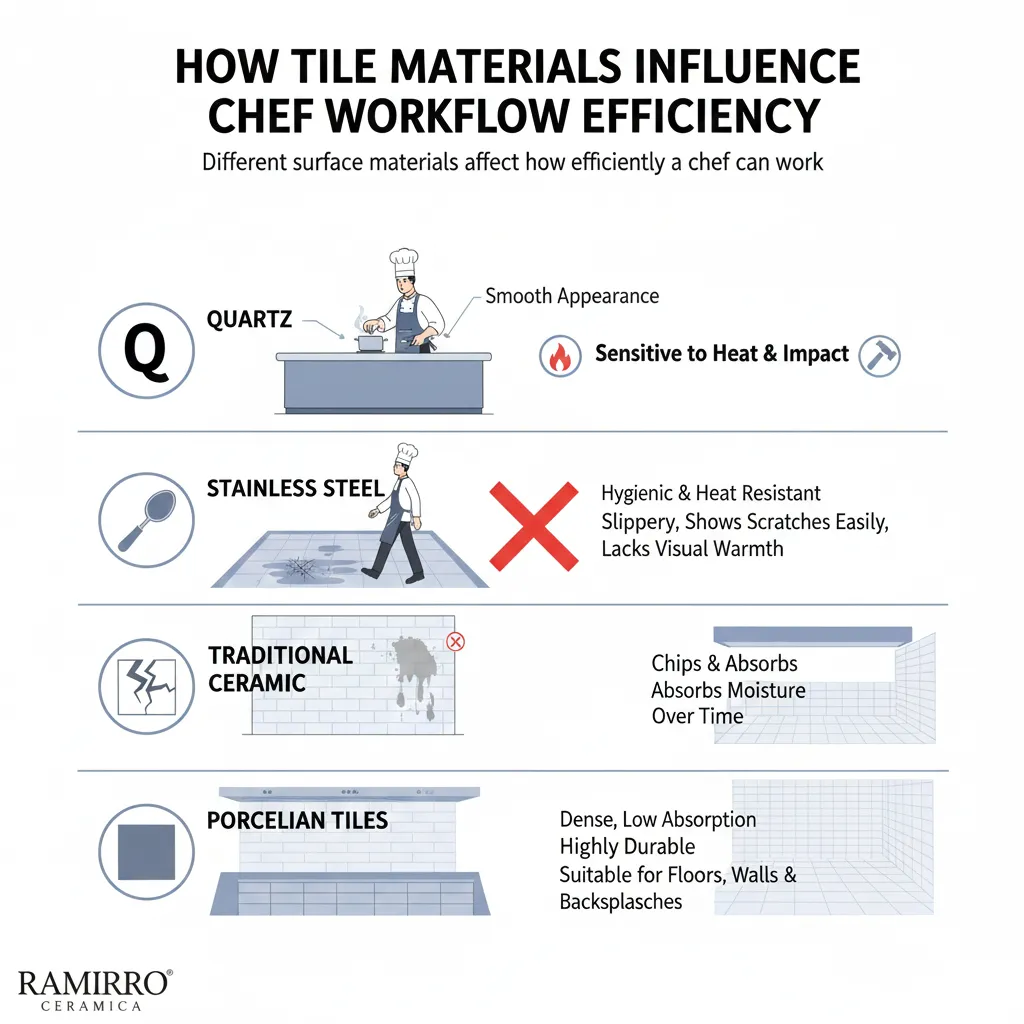

How Tile Materials Influence Chef Workflow Efficiency

Different surface materials affect how efficiently a chef can work.

Quartz offers a smooth appearance but can be sensitive to heat and impact in high temperature zones.

Stainless steel is hygienic and heat resistant but becomes slippery, shows scratches easily, and lacks visual warmth for flooring or walls.

Traditional ceramic tiles are suitable for light use but may chip or absorb moisture over time in heavy duty kitchens.

Porcelain tiles stand out because they are dense, low absorption, heat resistant, and highly durable, making them suitable for floors, walls, and backsplashes in demanding kitchen environments.

What Makes a Kitchen “Inspector Ready”? (Commercial Grade Standards)

Core Requirements Inspectors Look For

Cleanability standards

Inspectors expect kitchen surfaces to be smooth, washable, and non absorbent. Floors, walls, and backsplashes should not trap grease, food particles, or stains. Materials that clean easily reduce hygiene risks and support daily sanitation routines.

Moisture and mold resistance

Kitchens are high moisture environments. Inspectors check whether materials can resist water absorption and prevent mold or bacterial growth, especially near sinks, dishwashing areas, and cooking zones.

Slip resistance (R rating)

Floor safety is critical. Inspectors look for slip resistant flooring, especially in wet or oily areas. R rated tiles help reduce the risk of falls and are commonly required in commercial kitchens.

Heat and fire resistance near cooking zones

Areas around stoves, ovens, and grills must handle high temperatures safely. Inspectors assess whether wall and floor materials can withstand heat without damage or safety risks.

Surfaces with too many joints, cracks, or gaps are harder to clean and can trap dirt and moisture. Inspectors prefer continuous, well finished surfaces with minimal joints for better hygiene control.

Drainage and slope considerations

In commercial style or wet kitchens, proper floor slope and drainage help prevent water pooling. Inspectors check that floors guide water toward drains to maintain safety and cleanliness.

Why Tile Selection Directly Affects Inspection Outcomes

Tile choice plays a major role in whether a kitchen passes inspection. Tiles help define hygiene zones, work zones, and safety zones within the kitchen. The right tiles support cleaning, reduce slip risks, and handle heat and moisture without damage.

Poor tile selection often leads to inspection problems such as cracked flooring, absorbent joints, slippery surfaces, or stained walls. Well engineered tiles like porcelain tiles from Ramirro Ceramica offer low water absorption, slip resistant finishes, and durable surfaces that help kitchens remain safe, hygienic, and inspector ready over time.

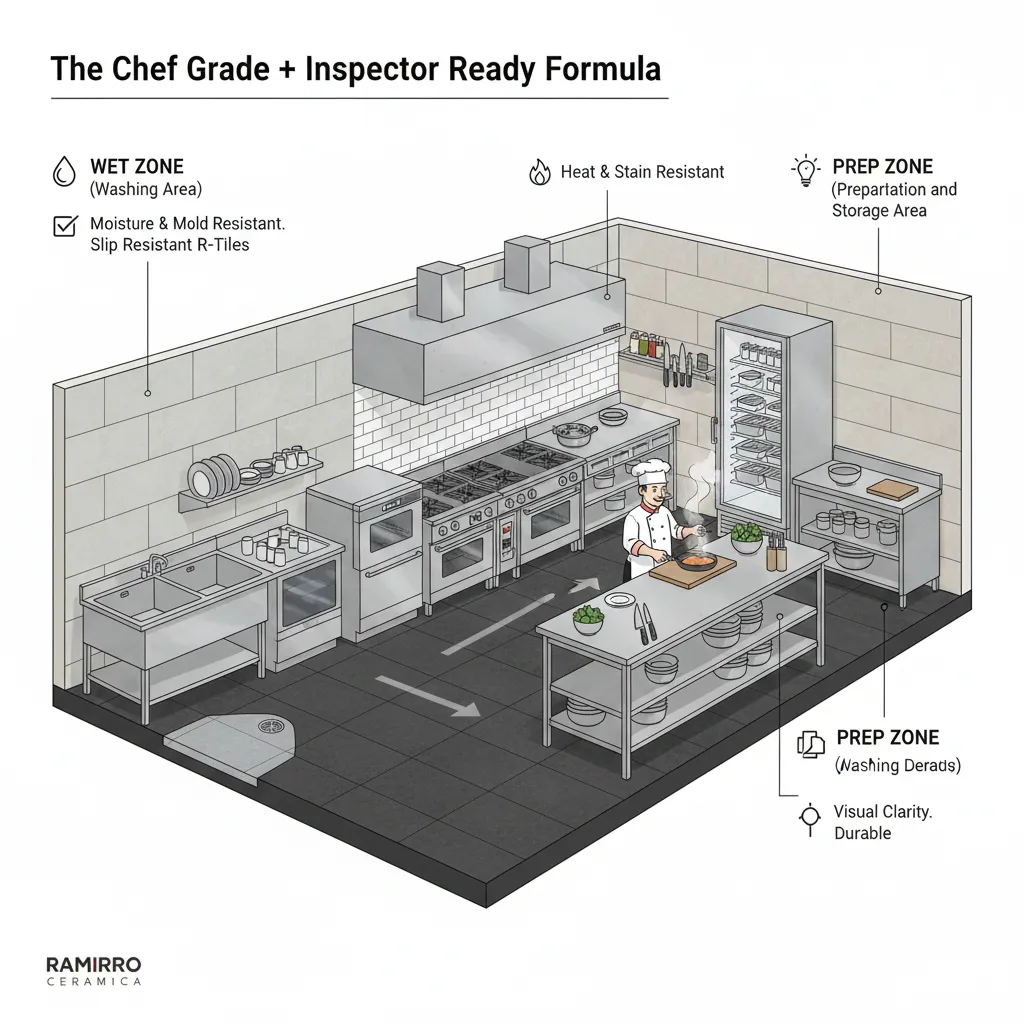

The Chef Grade + Inspector Ready Formula: Designed for Chefs, Approved by Inspectors

The 3 Zone System Used in Professional Kitchens

Hot Zone (Cooking Area)

This includes the cooking line, stove, oven, and backsplash areas. It faces constant heat, oil splashes, and heavy use. Materials here must resist high temperatures, stains, and frequent cleaning without losing strength or finish.

Wet Zone (Washing Area)

This zone covers sinks, dishwashing areas, and spaces exposed to water and detergents. Floors and walls here must handle moisture, prevent slipping, and resist mold or bacterial growth.

Prep Zone (Preparation and Storage Area)

This includes chopping, plating, cold prep, and storage areas. Cleanliness, impact resistance, and visual clarity are critical to prevent contamination and speed up workflow.

The Tile Performance Checklist for Each Zone

Hot Zone – Walls, Floors, and Counters

Heat resistant tiles that do not crack or discolor

Stain resistant, non porous surfaces for grease control

Large format wall tiles to reduce joints behind stoves

Wet Zone – Floors and Walls

Slip resistant (R rated) flooring for safety

Low water absorption tiles to prevent moisture damage

Easy to clean wall tiles extending high enough to block splashes

Prep Zone – Floors and Work Surfaces

Impact resistant tiles that handle dropped tools

Smooth, hygienic surfaces for fast sanitization

Consistent color and finish to spot spills quickly

How Ramirro Ceramica Tiles Are Engineered for Chef Grade Performance

-

Glaile 308×264 mm Glass & Ceramic Mosaic Tiles | GR Series | Made in Japan

Glaile 308×264 mm Glass & Ceramic Mosaic Tiles | GR Series | Made in Japan -

TK Series Tank Glossy Wall Tile Collection | Made in Japan | TK01–TK05

TK Series Tank Glossy Wall Tile Collection | Made in Japan | TK01–TK05 -

Zoid Tapered Porcelain Wall & Floor Tiles | 108×60 mm & 227×60 mm | ZO/2 Series – Made in Japan

Zoid Tapered Porcelain Wall & Floor Tiles | 108×60 mm & 227×60 mm | ZO/2 Series – Made in Japan -

Kurutoga Select Porcelain Tiles | 227×60 mm | Made in Japan

Kurutoga Select Porcelain Tiles | 227×60 mm | Made in Japan -

SILK CHERRY – Rustic Rose Red Color Tiles

SILK CHERRY – Rustic Rose Red Color Tiles -

HALE GREY Stone Terrazzo Rustic tiles

HALE GREY Stone Terrazzo Rustic tiles -

LATTE WHITE – Multiple Colors

LATTE WHITE – Multiple Colors -

LOTUS BROWN – Brick Red Color

LOTUS BROWN – Brick Red Color -

LOTUS LEAF – Grey color tiles

LOTUS LEAF – Grey color tiles -

MANDALA BREATH – Multicolours

MANDALA BREATH – Multicolours -

MAUVE Cream color rustic tiles

MAUVE Cream color rustic tiles -

MUSTED CLAY – Light Brown Color Tiles

MUSTED CLAY – Light Brown Color Tiles -

SEPIA BEIGE Tiles

SEPIA BEIGE Tiles -

SILK CROW – Pearl white rustic tiles

SILK CROW – Pearl white rustic tiles -

CACO GRAY Rustic Tiles

CACO GRAY Rustic Tiles -

CARAMEL BROWN Rustic Tiles

CARAMEL BROWN Rustic Tiles -

GRECA BLUE Rustic Tiles

GRECA BLUE Rustic Tiles -

GRECA BONE Rustic Tiles

GRECA BONE Rustic Tiles

Porcelain Body Advantage: Density, Hardness & Water Absorption < 0.5%

Porcelain tiles are fired at very high temperatures, making them dense and hard with extremely low water absorption (below 0.5%). This matters because liquids, oils, and food spills stay on the surface instead of soaking in. For hygiene and inspections, this means fewer chances of bacterial growth, staining, or moisture damage. Dense porcelain also resists cracking under heavy use, helping kitchens maintain long term durability and pass repeated inspections.

Heat Resistant Surfaces for Cooking Lines

Cooking areas face intense heat from frying, grilling, ovens, and tandoor cooking. Tile surfaces near these zones must tolerate high temperatures without discoloration or structural damage. Ramirro Ceramica porcelain tiles are suitable for backsplashes, wall cladding, and flooring around cooking lines, offering stability under heat and allowing frequent cleaning of oil splashes and soot without surface breakdown.

Slip Resistant Finishes (R9-R12 Options)

Slip resistance is measured using an R rating.

Lower R ratings offer basic grip in dry areas.

Higher R ratings provide better grip in wet or oily conditions.

Commercial kitchens often require R11 or higher in washing and wet zones because water, oil, and detergents make floors slippery. Ramirro Ceramica offers slip resistant finishes across R9 to R12, allowing designers to choose the right level of safety for each kitchen zone while meeting inspection requirements.

Anti Microbial & Stain Resistant Surfaces

Hygiene in a chef grade kitchen depends on how easily surfaces can be cleaned. Porcelain tiles use non porous glaze technology, which prevents stains, grease, and food particles from penetrating the surface. This reduces odor retention and supports daily sanitation routines. Because the surface does not absorb moisture, it naturally limits conditions where microbes can grow, helping kitchens stay cleaner and inspection ready.

Large Format Tiles for Fewer Joints + Better Hygiene

Large format porcelain slabs such as 800×1600, 1200×2400, and 1600×3200 mm reduce the number of joints on walls and floors. Fewer joints mean fewer places for dirt, grease, and moisture to collect. Chefs prefer these seamless surfaces because they are faster to clean, easier to maintain, and visually clearer during service. From an inspection perspective, fewer joints also mean improved hygiene control and reduced long term maintenance issues.

Kitchen Design Ideas That Achieve Chef Level Functionality

“Movement Mapping” Approach to Kitchen Layout

Plate to Pan Route

This is the chef’s main service path: from the pass or plating station to the cooking line. A clear, uncluttered route with minimal turns lets chefs deliver dishes quickly and safely. Designers can support this by placing the cooktop, finishing area, and pass within a straight line, using tile patterns or contrasting colors to visually guide the path.

Prep to Cook Route

This connects the main prep zone (chopping, marinating, mise en place) to the cookline. Chefs need to move ingredients efficiently without crossing into cleaning or storage zones. Use a different tile color or texture for prep and cooking areas to help home cooks and professionals intuitively follow the correct flow.

Raw to Wash Route

This is the path from raw food storage (meat, fish, produce) to the wash up area (sink, dishwashing). Keeping this route separate from cooked food zones prevents cross contamination. Tile based zoning such as a dark, textured tile for the wash area and a lighter, smooth tile for prep helps users identify and follow safe movement patterns.

Tile Based Zoning to Improve Efficiency

Contrasting tile colors/textures

Use different tile finishes or colors to mark functional zones (e.g., a matte, non slip tile for the wet zone, a smooth, easy clean tile for prep). This helps both chefs and inspectors visually confirm that each area is set up for its specific workflow.

Visual guidance

Even without changing the layout, contrasting tiles can help home cooks follow pro workflows. For example, a bright tile in the prep zone signals “work here,” while a darker, textured tile in the wash zone signals “clean up here.”

Heat Proof Design Details Every Chef Wishes Homeowners Knew

High heat backsplash tiles

Behind ovens, grills, and tandoors, use tiles specifically rated for high heat. Ramirro Ceramica’s porcelain tiles can withstand thermal shocks and do not release toxic fumes, making them ideal for these zones.

Counter slabs resistant to thermal shock

Countertops near cooking lines should be made from materials that won’t crack or discolor when hot pans are placed directly on them. Porcelain slabs are a durable, heat resistant choice.

Wall tiles behind ovens/tandoors

These areas are exposed to radiant heat and splashes. Dense, low porosity tiles prevent heat damage and are easy to clean, reducing the risk of fire and supporting long term hygiene.

Hygiene Focused Surfaces That Speed Up Cleaning

Matte vs glossy in hygiene critical areas

Matte tiles are preferred in high traffic and wet zones because they are less slippery and better at hiding minor marks. Glossy tiles are best for walls and backsplashes where visual clarity and easy wipe downs are needed.

Joint minimization strategies

Use large format tiles or slabs to reduce grout lines, which are hard to clean and can harbor bacteria. Fewer joints mean faster cleaning and better inspection results.

Tile skirts and tile cladded counters

Installing tile skirts or fully cladding counters with porcelain tiles creates seamless, easy to sanitize surfaces that chefs and inspectors both appreciate.

Why Tiles Outperform Other Materials in Chef Grade Kitchens

Tiles vs Marble vs Quartz vs Stainless Steel

| Performance Factor | Porcelain Tiles | Marble | Quartz | Stainless Steel |

|---|---|---|---|---|

| Heat Resistance | Excellent; withstands high cooking heat and hot utensils | Moderate; heat can cause discoloration or cracking | Limited; resins can scorch under high heat | Excellent; handles direct heat |

| Stain Resistance | High; non porous surface resists oil and food stains | Low; porous and easily stained | Moderate; resists stains but sensitive to chemicals | High; does not stain but shows marks |

| Water Absorption | Very low (<0.5%) | High; absorbs moisture | Low | None |

| Durability | Very high; resists impact, chipping, and wear | Low; prone to scratching and etching | Moderate; can chip or crack under impact | High, but dents and scratches easily |

| Hygiene Performance | Excellent; non porous and easy to sanitize | Poor; pores can trap bacteria | Good, but joints and seams need care | Good; hygienic but requires constant wiping |

| Cost Over Lifespan | Low; long life with minimal maintenance | High; expensive upkeep and replacement | Moderate; replacement needed if damaged | High; frequent maintenance to maintain appearance |

Why Porcelain Tiles Offer the Best Cost to Longevity Ratio

Porcelain tiles stand out because they combine heat resistance, hygiene, durability, and low maintenance in one material. Unlike marble, they do not absorb stains or moisture. Unlike quartz, they tolerate high temperatures without damage. And unlike stainless steel, they maintain appearance without constant polishing or repair.

Ramirro Ceramica enhances these advantages through advanced manufacturing processes that ensure consistent density, strength, and surface quality. With low water absorption, durable finishes, and large format options that reduce joints, Ramirro Ceramica’s porcelain tiles deliver long term performance with minimal upkeep; making them a practical, cost effective choice for chef grade kitchens that must stay safe, hygienic, and inspection ready for years.

Bringing Commercial Grade Precision into Home Kitchen Design with Ramirro Ceramica

A chef-grade kitchen focuses on performance, hygiene, and safety, and that is what truly sets a chef’s kitchen apart. Whether you are designing a chef’s kitchen, a chef-worthy kitchen, or a luxury kitchen, a well-designed kitchen isn’t defined only by an appliance, grade appliances, or a stylish cabinet; it is shaped by durable, easy to clean surfaces that support the full cooking process. From kitchen cabinets, cutting boards, and a functional kitchen island to the overall cooking space designed for real cooking techniques, every decision matters when you design a kitchen that delivers a better cooking experience.

An inspector ready, commercial grade kitchen relies on professional-grade materials that help keep your kitchen safe, hygienic, and easy to maintain, whether it’s for a home, a restaurant, or a shared kitchen and living space. With modern kitchen design and practical kitchen ideas that support daily use around the kitchen, Ramirro Ceramica tiles play an essential role in creating the ultimate cooking space. Their tiles combine durability and design ideas that will transform both a luxury kitchen design and a working cooking space, making Ramirro Ceramica a reliable choice for kitchens built for real performance.

Shop Now | Chat With Expert | View Catalogue

Why Should You Trust us?

Here’s what you get out of our article. Our team have various Ceramic Experts with experience of more than 25 Years, researches on problems our customer faces in tiling industry.

Ramirro Ceramica, – One of The Leading Tiles Manufacturer and Supplier globally, helps you people gain knowledgeable insight before making your purchase decision for products related to the floor and wall tiles.

So, we have closely monitored all kinds of trends in the ceramic tiles manufacturing world, from the old days of clay and plain color to modern digital, realistic-looking designs printed on ceramics with high-depth effects.

Our tiling Experts have seen thousands of different tiles patterns, sizes, materials, pricing, and installation techniques throughout their career.

Their expertise shared with you in simplified and organised way, helps you choose and make better decision before purchasing any flooring option available in market.

Brief about Company:

Ramirro is one of the finest Tiles manufacturers in India manufacturing porcelain and ceramic tiles. Our products have a variety of sizes and types of tiles ranging from Ceramics, porcelain, Full body etc. This helps you choose the perfect fit for your project. Plus, our collection will help you get inspiration from the architect’s design.

Here’s some more helpful links that showcase our users trust on Ramirro Ceramica Brand:

– Growth in International Market

– Trusted and Licensed Exporter

– Manufacturing Plant in India

Here’s our social proof by LinkedIn competing with top known global tiling brands: