Morbi, known as the tile capital of India, has taken a giant leap forward in global exports with the development of the ICD Morbi (Inland Container Depot). This game-changing logistics hub is helping tile manufacturers streamline the shipping process like never before. ICD Morbi offers faster container movement, on-site customs clearance, and reduced shipping costs—all from a location just minutes away from major tile production units. By leveraging the full power of this inland container facility, exporters can deliver high-quality tiles to international markets with greater speed, safety, and efficiency. In this article, we explore how the inland container depot is transforming the tile export supply chain and why it’s a major advantage for global buyers.

- The Secret Logistics Weapon Behind Morbi’s Tile Export Boom

- Beyond Port Congestion: Why Inland Container Depots (ICDs) Are Reshaping Global Tile Logistics

- Not Just Faster — Smarter: How ICD Morbi Cuts Deadweight Costs

- From Factory Floor to Ship Deck: Ramirro’s 3-Day Turnaround Strategy

- Avoiding the Common Export Pitfalls — Lessons from ICD Morbi Operations

- ICD vs CFS: Understanding the Real Cost and Efficiency Gains for Tile Exporters

- Beyond Speed: How ICD Morbi Enhances Quality Assurance

- ICD Morbi’s Role in Global Expansion: Ramirro’s Export Reach

- Ready to Import Quality Tiles Faster? Here’s Why Global Buyers Trust Ramirro

The Secret Logistics Weapon Behind Morbi’s Tile Export Boom

Morbi has long been celebrated as India’s leading hub for ceramic and porcelain tiles. But beyond its factories and showrooms, a quiet logistics revolution is taking place—powered by the ICD Morbi (Inland Container Depot). This inland container facility is not just a supporting actor in the tile trade; it’s a strategic game-changer.

Located close to the manufacturing clusters, ICD Morbi significantly reduces the time and effort required to move finished tiles to port. Exporters no longer need to send goods to distant container freight stations (CFS) for customs procedures. Instead, everything from documentation to container sealing happens right at the depot.

Key benefits of ICD Morbi include:

Proximity to tile manufacturers, minimizing transport time from factory to freight.

On-site customs clearance, reducing delays and logistical bottlenecks.

Faster shipping turnaround, improving supply chain reliability and delivery commitments.

By transforming how goods flow from production to export, inland container depots like ICD Morbi are making Morbi not just a tile hub—but a global logistics powerhouse.

Beyond Port Congestion: Why Inland Container Depots (ICDs) Are Reshaping Global Tile Logistics

As global supply chains evolve, inland container depots (ICDs) are becoming critical to efficient tile exports. Located away from traditional seaports, ICDs like the one in Morbi offer exporters like Ramirro Ceramica a powerful advantage: reduced port congestion, quicker customs clearance, and lower costs.

Unlike regular container routes that rely heavily on overburdened seaports, ICD Morbi functions as a fully equipped container freight terminal—offering everything from customs inspection to container sealing on-site. This streamlines the logistics and supply chain, making it easier for exporters to manage bulk shipments without delays.

Advantages of inland container depots include:

Seamless connectivity to major ports like Mundra via road and rail.

Avoidance of delays commonly seen at container freight stations (CFS).

Consolidated value-added services such as warehousing, inspection, and pre-clearance.

Not Just Faster — Smarter: How ICD Morbi Cuts Deadweight Costs

Speed is important—but efficiency is what truly defines smart logistics. The ICD Morbi (Inland Container Depot) does more than just accelerate the tile export process; it significantly reduces transport overheads that often go unnoticed yet impact profit margins.

Traditionally, exporters had to move loaded containers to ports like Mundra or Kandla for customs clearance—adding unnecessary distance, fuel consumption, and handling costs. With ICD Morbi, that extra leg is eliminated. Containers are now loaded, inspected, sealed, and cleared for export—all within Morbi itself.

This shift brings clear savings:

Lower fuel costs due to reduced container mileage.

Fewer touch points, which means lower risk of damage or delays.

Reduced carbon footprint, supporting a more sustainable supply chain.

From Factory Floor to Ship Deck: Ramirro’s 3-Day Turnaround Strategy

In the competitive world of global tile exports, speed without compromise on quality is a rare achievement. Ramirro Ceramica has mastered this with a streamlined, 3-day logistics protocol powered by the ICD Morbi (Inland Container Depot).

By leveraging the proximity and efficiency of this inland logistics hub, Ramirro minimizes delays, reduces handling, and keeps the export process tightly coordinated from end to end.

Day 1: Final Inspection & Packaging

Tiles are quality-checked, packed, and palletized at Ramirro’s facility—ready for immediate loading.

Day 2: Container Loading at ICD Morbi

Containers are delivered to the inland container depot, where goods are stuffed, sealed, and digitally logged.

Day 3: Customs Clearance & Dispatch to Port

With customs procedures handled on-site, the container is cleared and trucked directly to the nearest port for shipping.

Avoiding the Common Export Pitfalls — Lessons from ICD Morbi Operations

Exporting tiles isn’t just about moving goods—it’s about moving them on time, within budget, and without error. Many exporters struggle with delays due to incomplete documentation, unreliable container handlers, or lack of access to an inland container depot. But Ramirro Ceramica avoids these pitfalls with a system that’s been built around precision and accountability.

At the core of this success is ICD Morbi. Exporters who lack direct access to this facility often face:

Missed vessel cut-offs due to delays in documentation or customs procedures.

Double handling at container freight stations (CFS), adding time and cost.

Lack of visibility into the export timeline, leading to shipment bottlenecks.

Ramirro’s approach is different.

An in-house documentation team prepares pre-clearance files well in advance, avoiding customs rejections or delays.

Only certified shipping agents and verified container yard teams are used, ensuring each container is handled with care and compliance.

With all formalities completed directly at the inland container depot, the process is faster, safer, and more transparent.

ICD vs CFS: Understanding the Real Cost and Efficiency Gains for Tile Exporters

A common confusion among international buyers is the difference between a container freight station (CFS) and an inland container depot (ICD). While both handle container freight, their functions and cost structures vary greatly—especially when you’re exporting large volumes of heavy materials like tiles.

ICDs, like the one Ramirro Ceramica uses in Morbi, are customs-notified inland facilities that provide end-to-end services. They eliminate the need to move goods to a distant port for clearance, significantly reducing the costs associated with inland container movement.

CFS facilities are often limited to container stuffing or de-stuffing and rely on external customs clearance—leading to more handling, delays, and higher overhead.

Key differences and cost advantages:

ICDs offer full customs clearance on-site, reducing paperwork and dwell time.

CFSs typically involve more third-party handling and longer timelines.

ICD operations result in fewer container transfers, reducing the risk of breakage—a major win for fragile tile shipments.

By choosing ICD Morbi over a standard container freight station (CFS), exporters benefit from quicker transit times, fewer logistics errors, and significant cost savings—advantages that ultimately improve competitiveness in global tile markets.

Beyond Speed: How ICD Morbi Enhances Quality Assurance

While faster exports are a major benefit of the inland container depot, ICD Morbi also plays a crucial role in improving product integrity and shipment reliability. For tile exporters like Ramirro Ceramica, quality doesn’t end at the factory—it extends all the way to the container gate.

One of the key advantages of ICD operations is that containers are sealed on-site after inspection and loading. This drastically reduces the risk of damage during transit, as there’s minimal re-handling between the factory and port.

Here’s how ICD Morbi supports better quality assurance:

Reduced handling = reduced breakage. With direct container loading and on-site sealing, the number of touch points is minimized, leading to fewer product claims and lower insurance-related issues.

On-site QA protocols. Ramirro’s quality assurance team is actively involved at the depot stage, conducting final visual and load stability checks before the container is sealed.

Secure inland container movement. The sealed container travels directly from ICD Morbi to the port, eliminating exposure to external tampering or improper storage at container freight stations (CFS).

ICD Morbi’s Role in Global Expansion: Ramirro’s Export Reach

The inland container logistics model at ICD Morbi has become a cornerstone of Ramirro Ceramica’s ability to scale globally while maintaining reliability. By operating from a location that combines proximity to manufacturing with integrated export services, Ramirro can fulfill international orders faster and with greater consistency.

Today, tiles shipped from ICD Morbi reach customers across the globe, with major export destinations including:

United States — New York, Texas, Florida

Europe — Germany, Italy, United Kingdom

Middle East — UAE, Saudi Arabia

Africa — South Africa, Egypt

Thanks to the seamless inland container movement and time-saving logistics handled at the depot, Ramirro can confidently commit to delivery timelines—even in high-demand markets. Fewer delays, reduced container handovers, and smarter routing mean international buyers receive their shipments with speed, security, and predictable quality.

In a world where supply chain reliability defines brand trust, ICD Morbi ensures that tile shipments arrive on time and in perfect condition—anywhere on the map.

Ready to Import Quality Tiles Faster? Here’s Why Global Buyers Trust Ramirro

If you’re looking to import premium-quality tiles with speed, reliability, and zero hassle, now is the time to connect with Ramirro Ceramica’s export team. Backed by streamlined logistics through ICD Morbi and years of export experience, we ensure that your tiles reach the nearest port on time and in perfect condition. Whether you’re sourcing for large-scale projects or quick retail needs, we handle everything—from samples to full container shipments—with efficiency and care.

Contact us today to explore product options, shipping timelines, and exclusive export support.

Ask how fast we can ship tiles to your nearest port — you’ll be surprised.

Shop Now | Chat With Expert | View Catalogue

Why Should You Trust us?

Here’s what you get out of our article. Our team have various Ceramic Experts with experience of more than 25 Years, researches on problems our customer faces in tiling industry.

Ramirro Ceramica, – One of The Leading Tiles Manufacturer and Supplier globally, helps you people gain knowledgeable insight before making your purchase decision for products related to the floor and wall tiles.

So, we have closely monitored all kinds of trends in the ceramic tiles manufacturing world, from the old days of clay and plain color to modern digital, realistic-looking designs printed on ceramics with high-depth effects.

Our tiling Experts have seen thousands of different tiles patterns, sizes, materials, pricing, and installation techniques throughout their career.

Their expertise shared with you in simplified and organised way, helps you choose and make better decision before purchasing any flooring option available in market.

Brief about Company:

Ramirro is one of the finest Tiles manufacturers in India manufacturing porcelain and ceramic tiles. Our products have a variety of sizes and types of tiles ranging from Ceramics, porcelain, Full body etc. This helps you choose the perfect fit for your project. Plus, our collection will help you get inspiration from the architect’s design.

Here’s some more helpful links that showcase our users trust on Ramirro Ceramica Brand:

– Growth in International Market

– Trusted and Licensed Exporter

– Manufacturing Plant in India

Here’s our social proof by LinkedIn competing with top known global tiling brands:

-

DOVE – Grey Full Body Tiles

DOVE – Grey Full Body Tiles -

SINTETICO-GREY Marble Look Porcelain Tiles

SINTETICO-GREY Marble Look Porcelain Tiles -

SINTETICO BIANCO Marble Look Porcelain Tiles

SINTETICO BIANCO Marble Look Porcelain Tiles -

SAHARA-GREY Marble Look Porcelain Tiles

SAHARA-GREY Marble Look Porcelain Tiles -

MYSTIQUE CREMA Marble Look Porcelain Tiles

MYSTIQUE CREMA Marble Look Porcelain Tiles -

MONTERA RIO Marble Look Porcelain Tiles

MONTERA RIO Marble Look Porcelain Tiles -

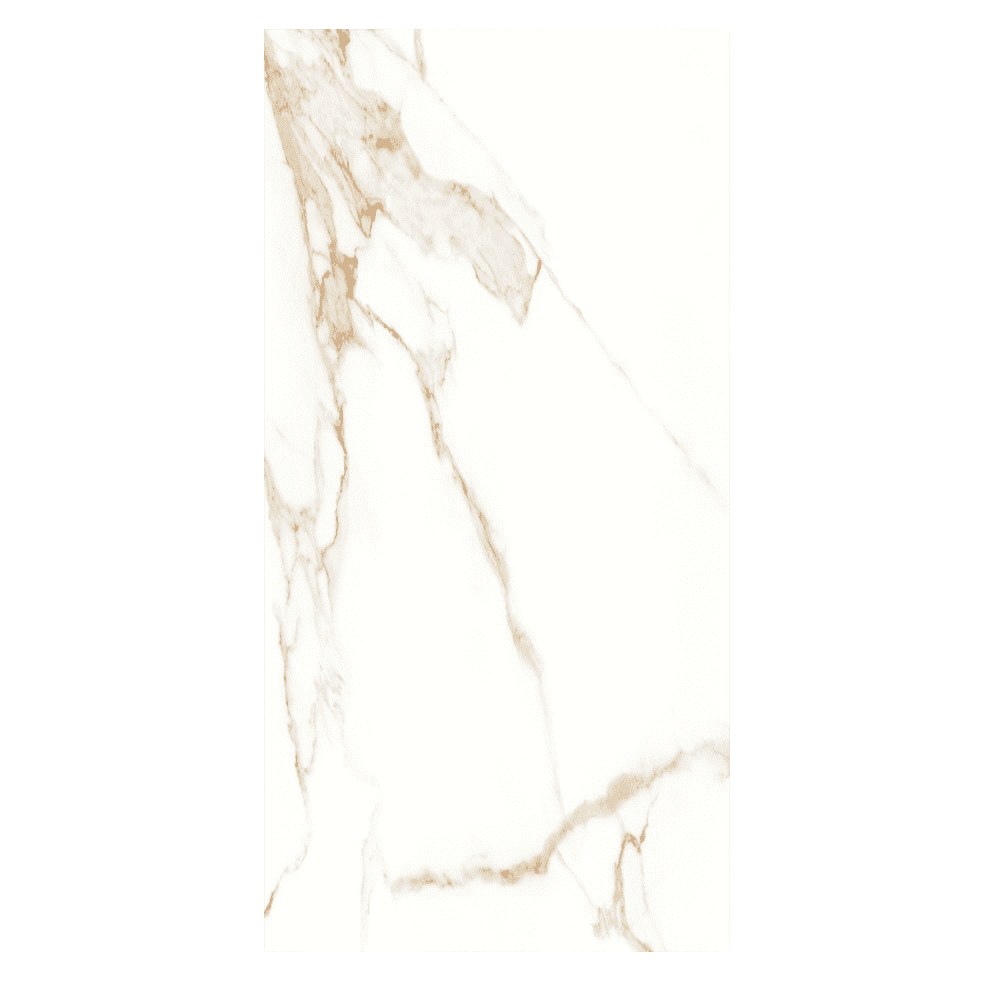

CALCATTA ORO Marble Look Porcelain Tiles

CALCATTA ORO Marble Look Porcelain Tiles -

APEN SILVER Marble Look Porcelain Tiles

APEN SILVER Marble Look Porcelain Tiles -

TERRAZZO BEIGE Marble Tile Design for Porcelain

TERRAZZO BEIGE Marble Tile Design for Porcelain -

TROPICANA WHITE Marble Tile Design for Porcelain

TROPICANA WHITE Marble Tile Design for Porcelain -

WILLIAM GREY Marble Tile Design for Porcelain

WILLIAM GREY Marble Tile Design for Porcelain -

TROPICANA CREMA Marble Tile Design for Porcelain

TROPICANA CREMA Marble Tile Design for Porcelain -

TRAVENTINO ROYAL Marble Tile Design for Porcelain

TRAVENTINO ROYAL Marble Tile Design for Porcelain -

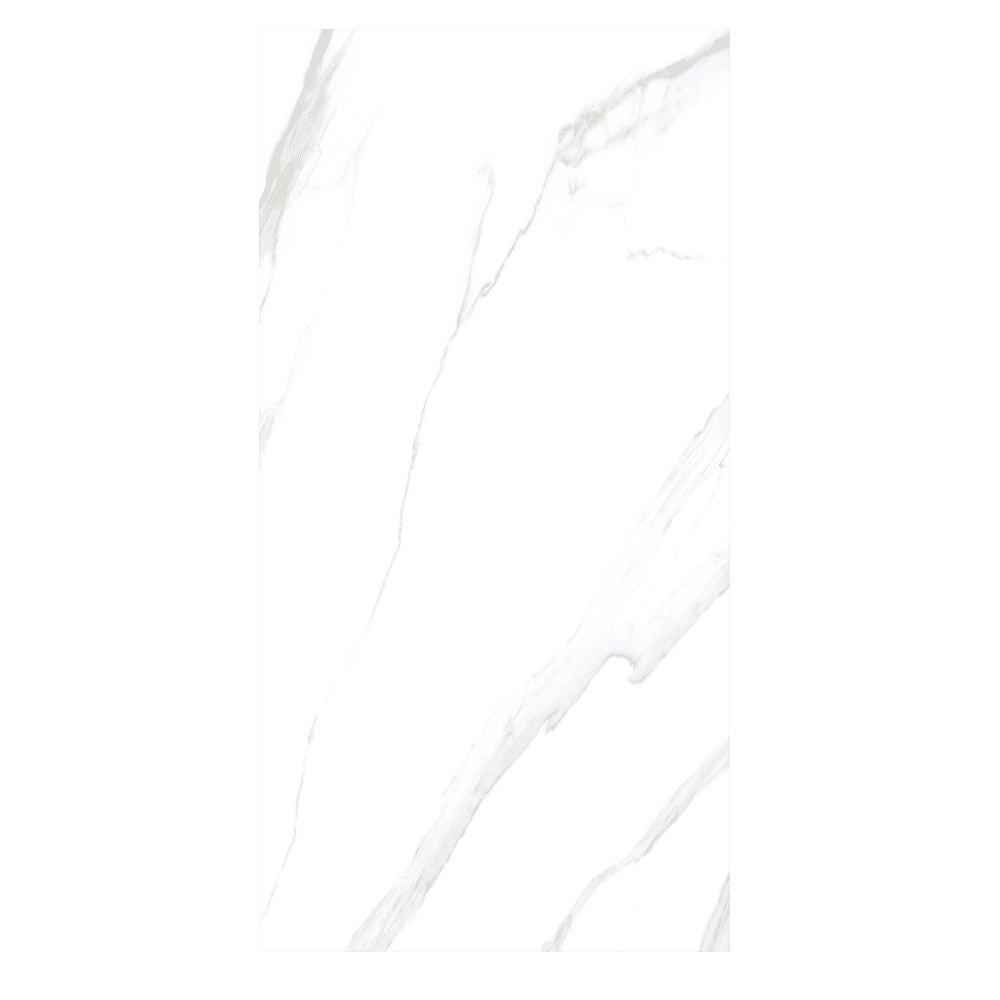

STATUARIO PEARL Marble Tile Design for Porcelain

STATUARIO PEARL Marble Tile Design for Porcelain -

STATUARIO GOLD Marble Tile Design for Porcelain

STATUARIO GOLD Marble Tile Design for Porcelain -

SEAMLESS STATUARIO Marble Tile Design for Porcelain

SEAMLESS STATUARIO Marble Tile Design for Porcelain -

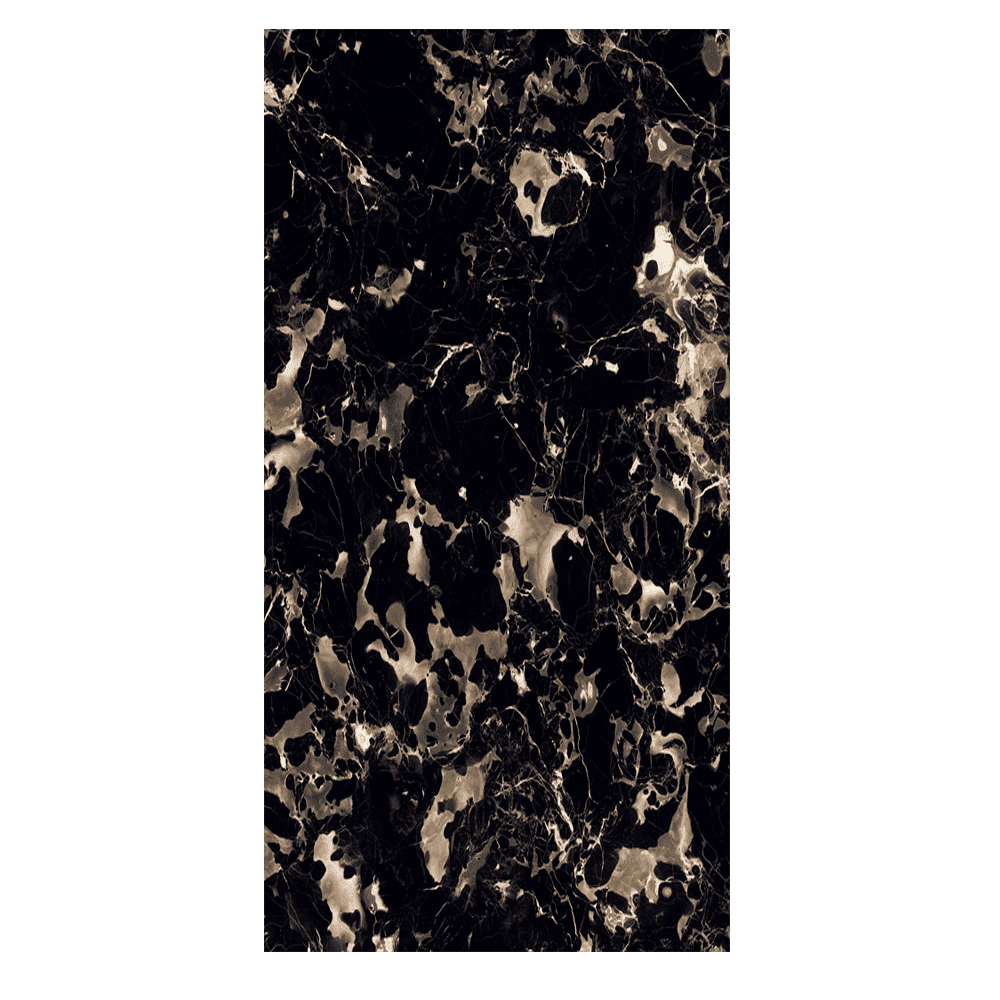

PORTORO BLACK Marble Tile Design for Porcelain

PORTORO BLACK Marble Tile Design for Porcelain -

NOVANA GREY Marble Tile Design for Porcelain

NOVANA GREY Marble Tile Design for Porcelain